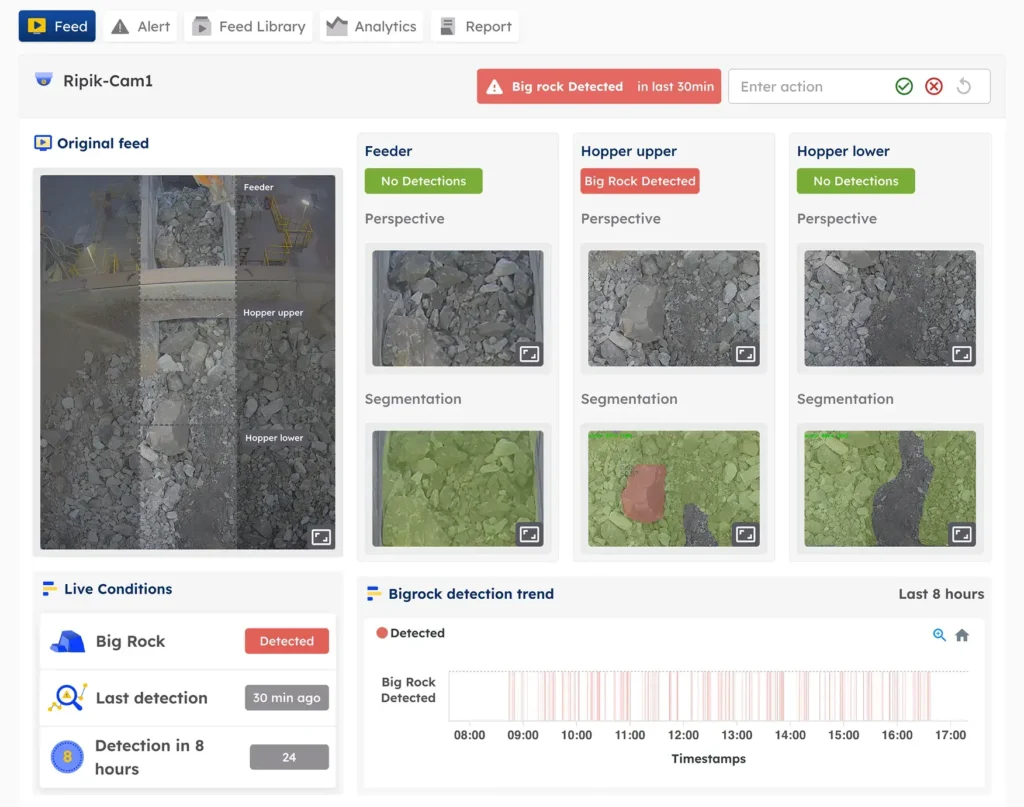

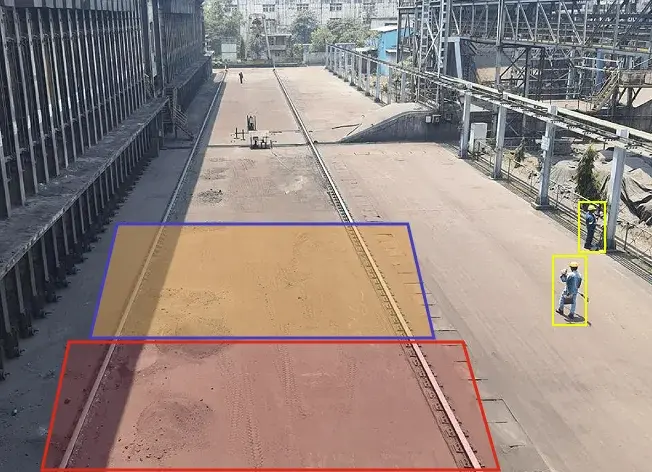

Pusher Car Turnaround Time Cycle Monitoring And Geo-fencing System For Productivity and Safety

With accurate real-time monitoring of Pusher Car Turnaround Time (TAT) and human geo-fencing, the system delivered a 1–2% productivity increase while improving resource utilization and reducing operational wastage.