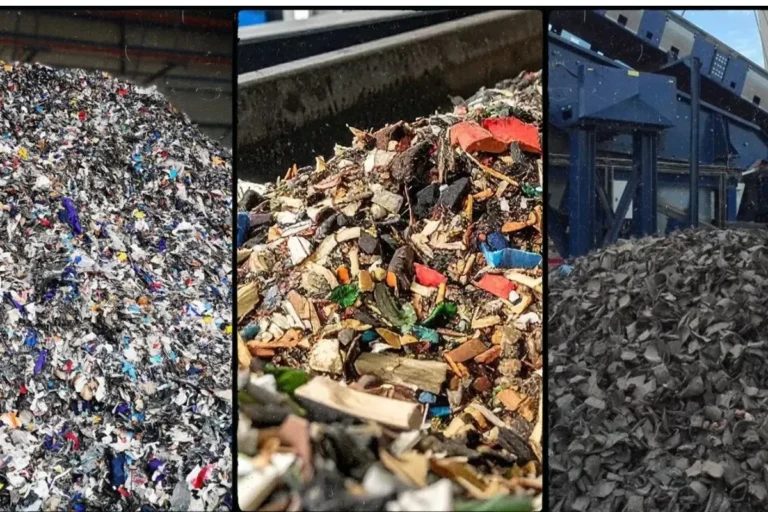

Ripik.AI focuses on reducing operational variability through optimal process control. We implemented our patented Cognitive and Vision AI based solution Ripik Vision, capable of particle differentiation based on color, moisture and size. With the plant team interaction and first-hand process control, we swiftly delved into comprehending their requirements.

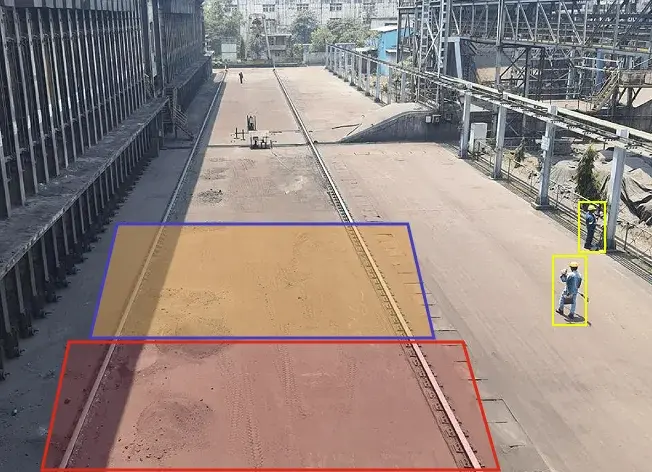

- Real-time coke sizing by Ripik Vision increased their coke sampling from 3/day to 4000/day for an efficient input feed control.

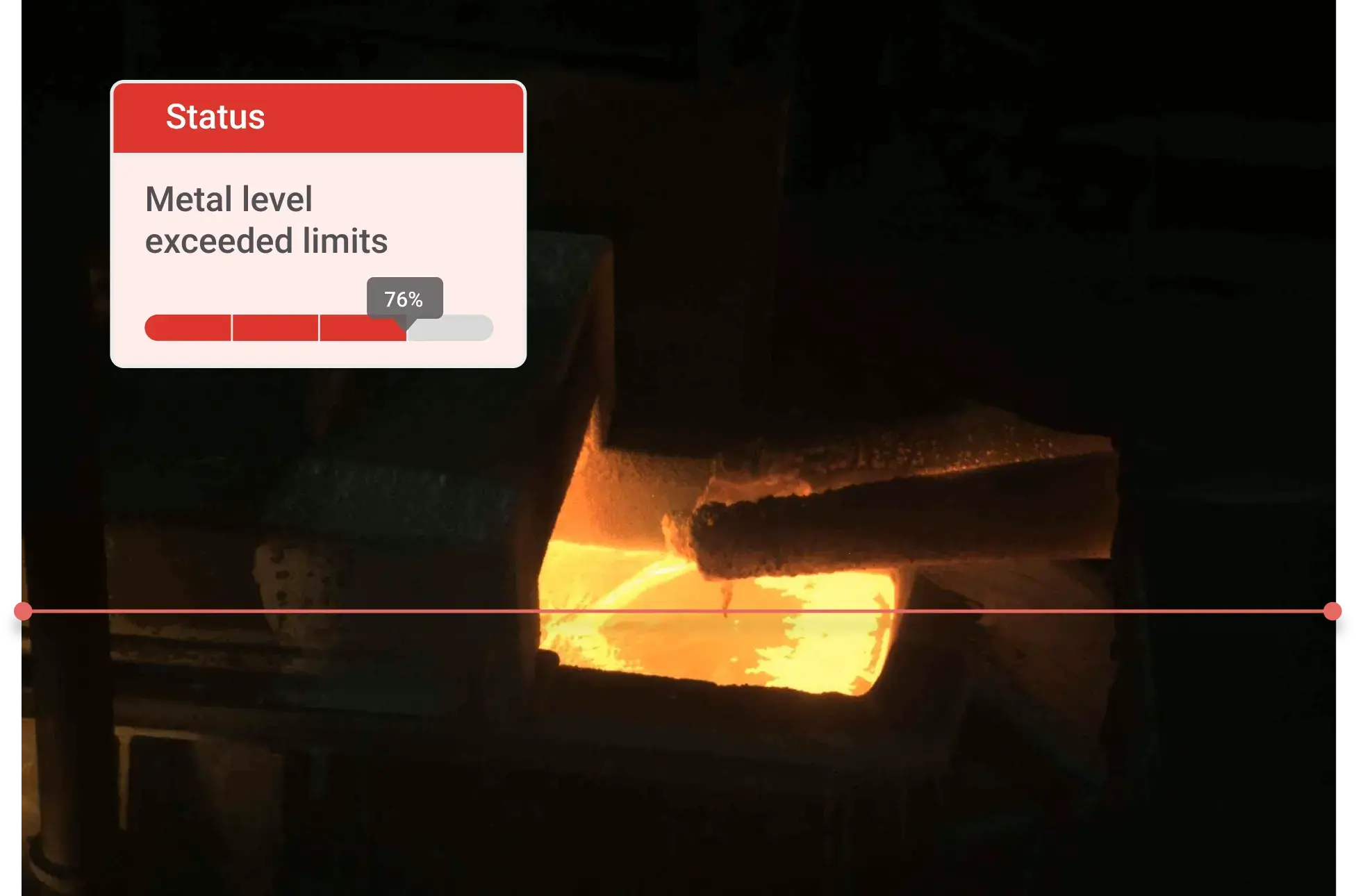

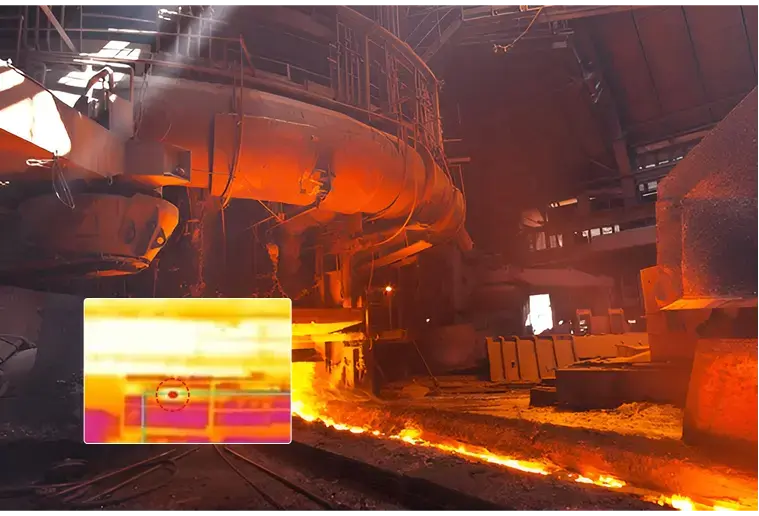

- It helped the team to pinpoint the anomalies contributing to the increased fuel rate in the furnace.

- Also, the solution predicted slag chemistry and hot metal silicon, scrap quality in Electric Arc Furnaces (EAF).

This approach empowered operators to optimize fuel efficiency, enhance furnace performance, and contribute to more efficient and sustainable operations.