AI in the mining industry is not merely a trend; it’s a necessity. With vast operations often spread across remote and hazardous environments, real-time insights and automation are key to minimizing human error, optimizing production, and maintaining sustainability.

Discover how AI is transforming plant uptime in manufacturing by enabling predictive maintenance, real-time anomaly detection, and SOP compliance. Improve equipment reliability, reduce unplanned downtime, and enhance overall operational efficiency

Agentic AI in manufacturing operations are designed, executed, and optimized. These systems act autonomously, making decisions based on real-time data to improve efficiency, reduce costs, and maintain high product quality

Root Mean Square Error (RMSE) is a widely used metric that measures the average magnitude of prediction errors in a model. It calculates the square root of the mean of squared differences between actual and predicted values, providing insight into model accuracy. Lower RMSE values indicate better predictive performance.

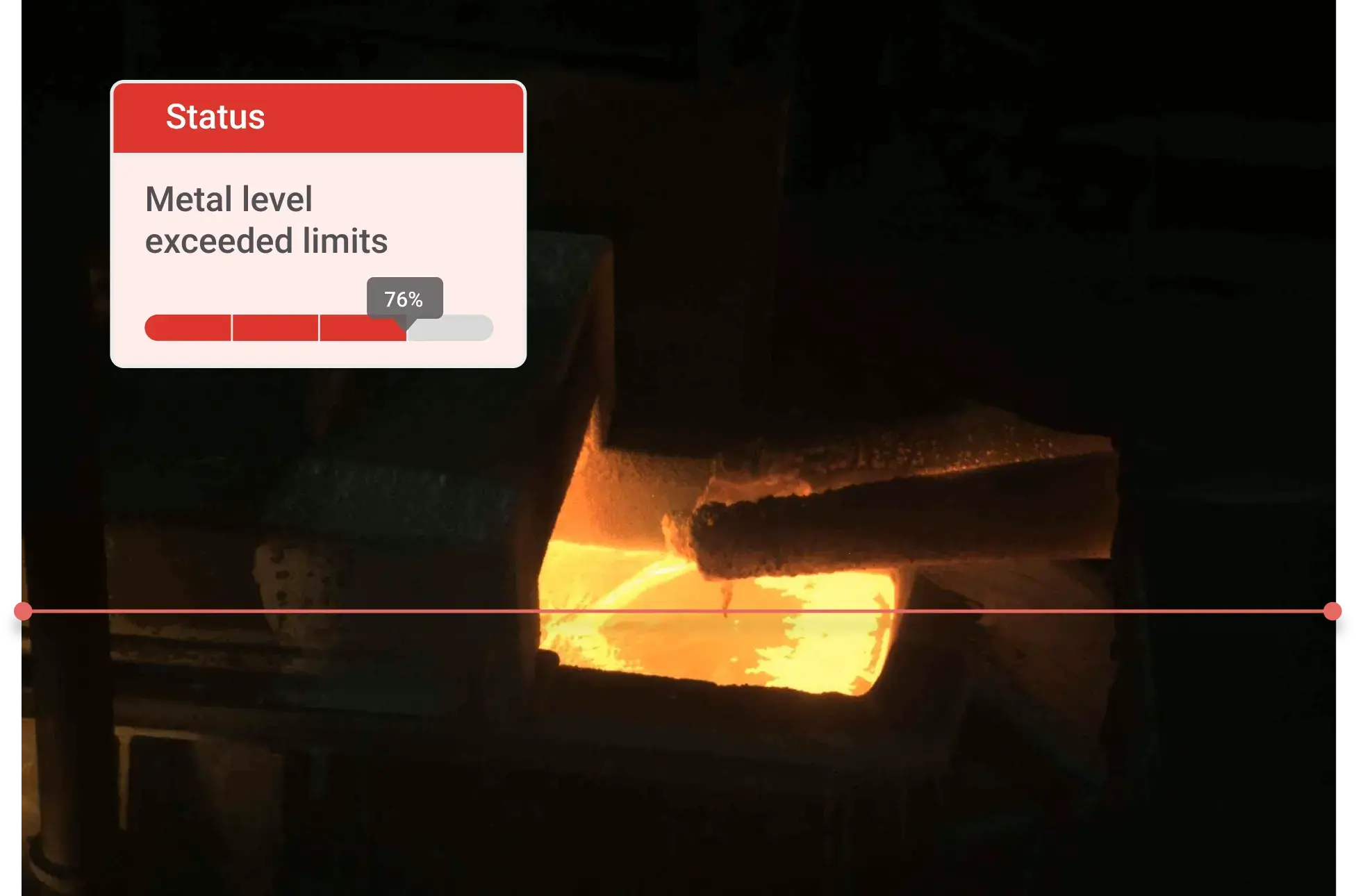

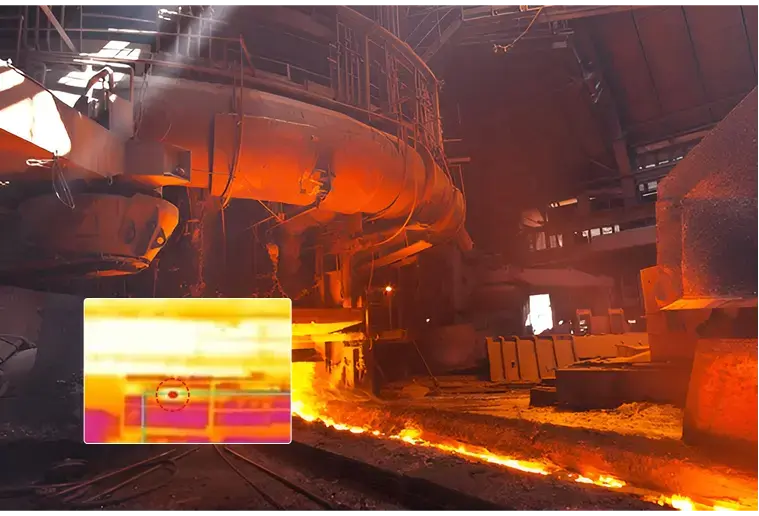

The blast furnaces steelmaking process is a complex and requires precise control over various parameters. Artificial Intelligence (AI) is optimizing this process, enhancing both productivity and quality.

AI platforms for anomaly detection are transforming a wide range of industries by leveraging advanced machine learning and deep learning algorithms to proactively identify potential issues, enabling businesses to mitigate risks and improve efficiency.

The role of AI in enhancing energy efficiency in cement plants particularly in fuel Consumption is significant portion of cement production expenses. Real-time monitoring, predictive analytics, and optimization of plays a key role in this.

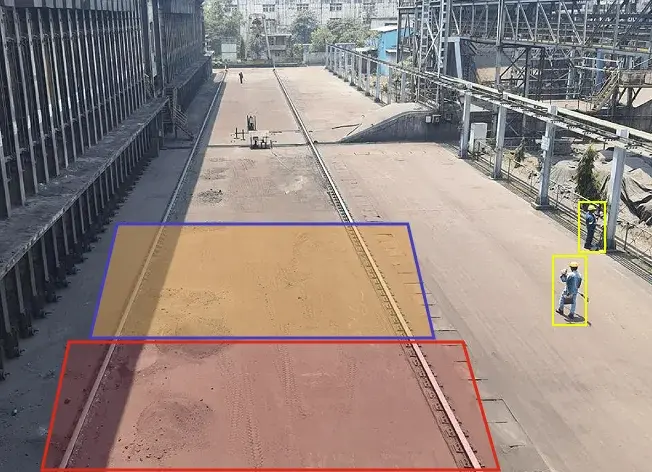

Vision AI agent operate through a structured pipeline involving perception, analysis, decision-making, and continuous learning. By leveraging computer vision, deep learning, and real-time processing, these agents enable automation, predictive analytics, and intelligent decision-making across industries.

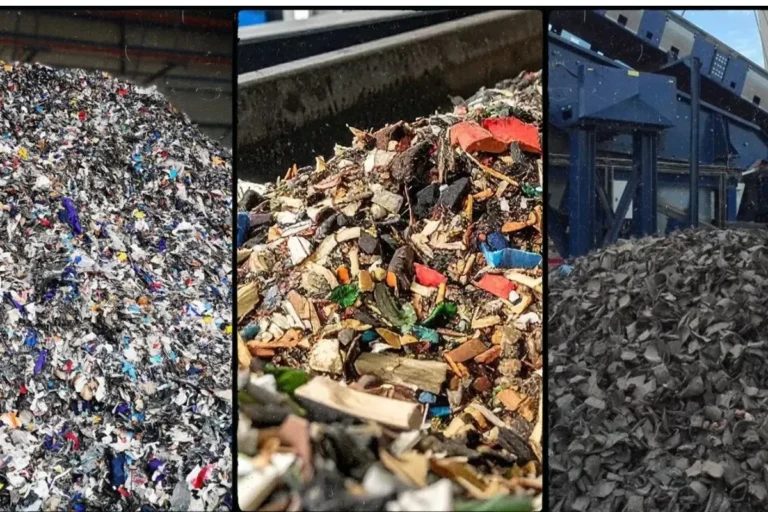

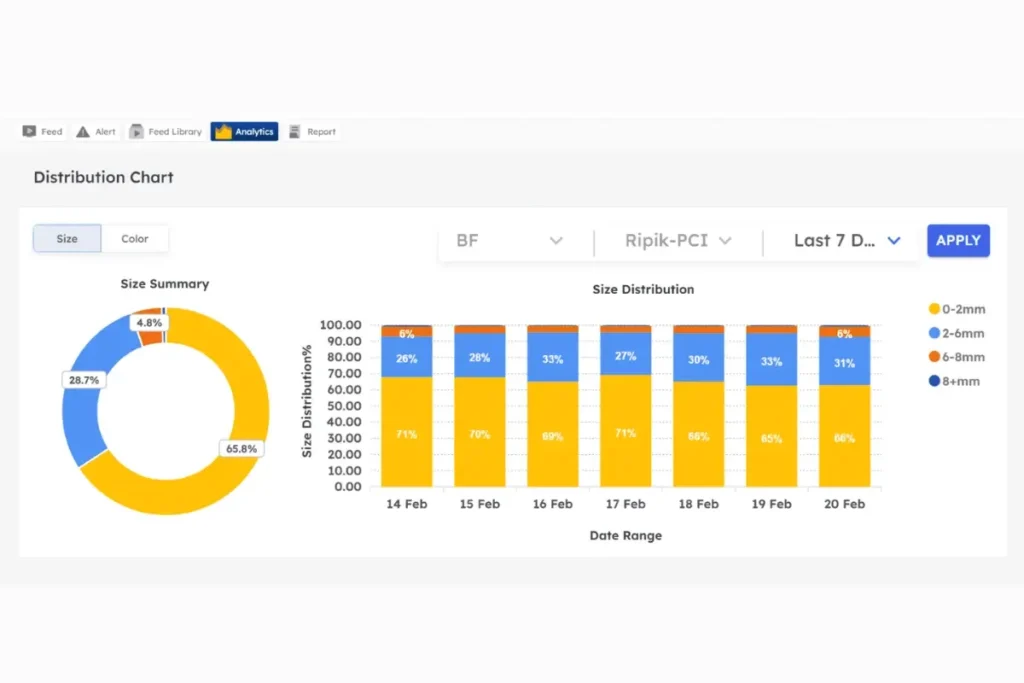

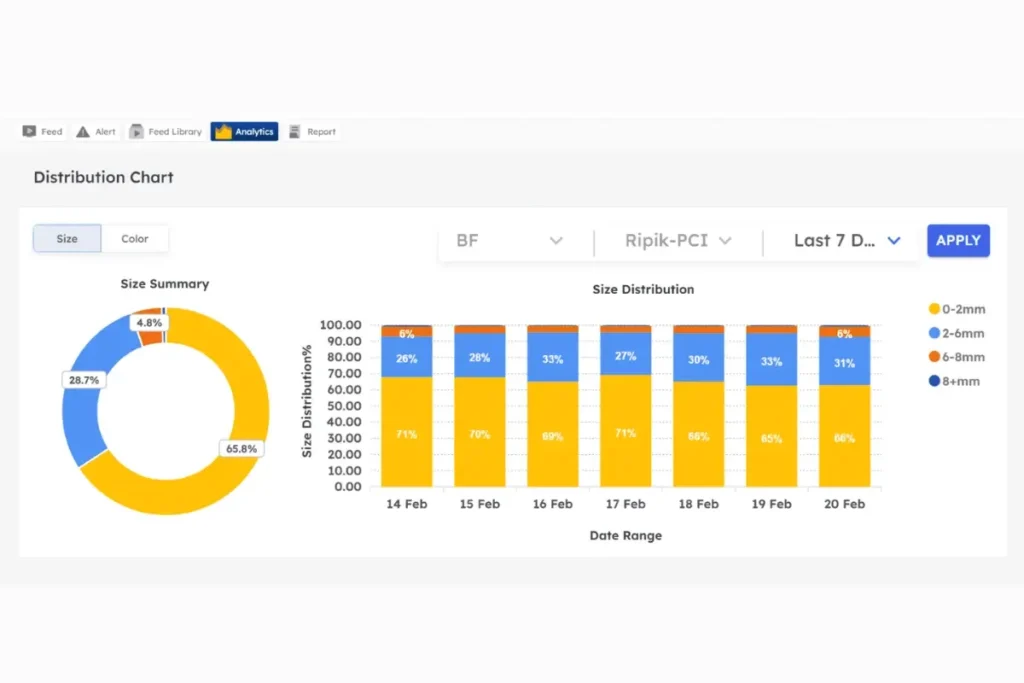

Particle size analysis plays a critical role in heavy industries such as cement, mining, steel, and power plants. Particle size distribution impacts product quality, process efficiency, and overall operational costs.

Conveyor volume scanners are revolutionizing stockpile management by providing precise, real-time data to enhance material flow, inventory control, and operational efficiency. Using advanced technologies like LIDAR and Vision AI, these systems help reduce waste, optimize production, and improve safety across industries such as steel manufacturing, mining, cement, and logistics.