AI Platforms for Flare Monitoring

What is a Flare in Industrial Plants?

A flare in industrial plants is a safety system used to burn excess or hazardous gases such as methane, propane, hydrogen sulfide, and flared gases in a controlled manner. It operates during startups, shutdowns, emergencies, process upsets, and maintenance activities. Flaring prevents dangerous pressure buildup and avoids the release of flammable or toxic gases into the atmosphere. It is widely used in the oil & gas, refinery, petrochemical, and chemical plant industries, as well as in power generation, cement, steel, and waste incineration. Flares play a critical role in protecting equipment and personnel while ensuring safety and environmental compliance.

Problems Faced in Flares or Flare Gas Monitoring

Flare and flare gas monitoring is critical for ensuring safe, efficient, and compliant plant operations, but it is often challenged by harsh environments, complex gas behavior, and limitations of conventional measurement systems. Below are the major challenges faced in flare monitoring.

- Incomplete or inefficient combustion results in black smoke, soot formation, and higher emissions.

- Poor visibility at the flare tip due to smoke, steam, dust, weather conditions, and sunlight glare

- Inaccuracies caused by tar deposition, fouling, and flow meter malfunctions lead to incorrect gas flow measurements and making it difficult to accurately measure flare performance and emissions.

- Difficulty in correlating flame size and behavior with actual gas flow rates, despite the strong dependence between the two

- Undetected flame failure, especially during daytime or adverse operating conditions, highlights the need for technology that reliably detects flame presence.

- Harsh operating environments (extreme heat, corrosive gases, vibration) reduce sensor reliability and lifespan.

- Limited monitoring coverage for large or multiple flare stacks, creating blind spots

- Delayed response due to manual monitoring, increasing operational and safety risks

- Sustainability and ESG challenges, as inaccurate monitoring increases emissions and reporting uncertainty

- Safety risks, including unburned gas release, fire hazards, and non-compliance with regulations

Selecting the right method for monitoring flare operation and combustion efficiency is challenging due to varying site conditions and technology limitations. Quantifying removal efficiency and smoke index in real time is also difficult because of the harsh and dynamic flare environment.

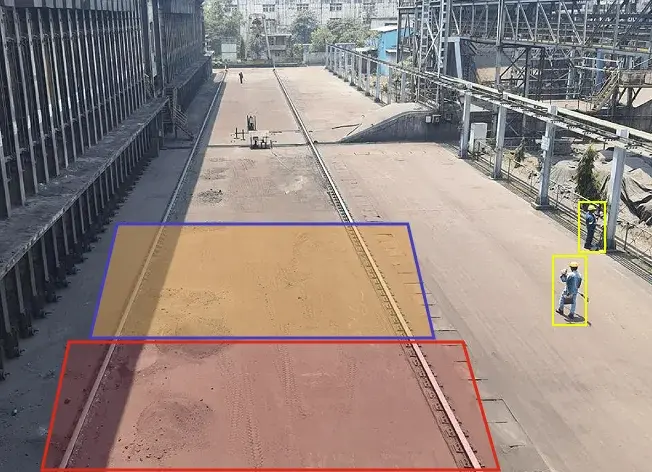

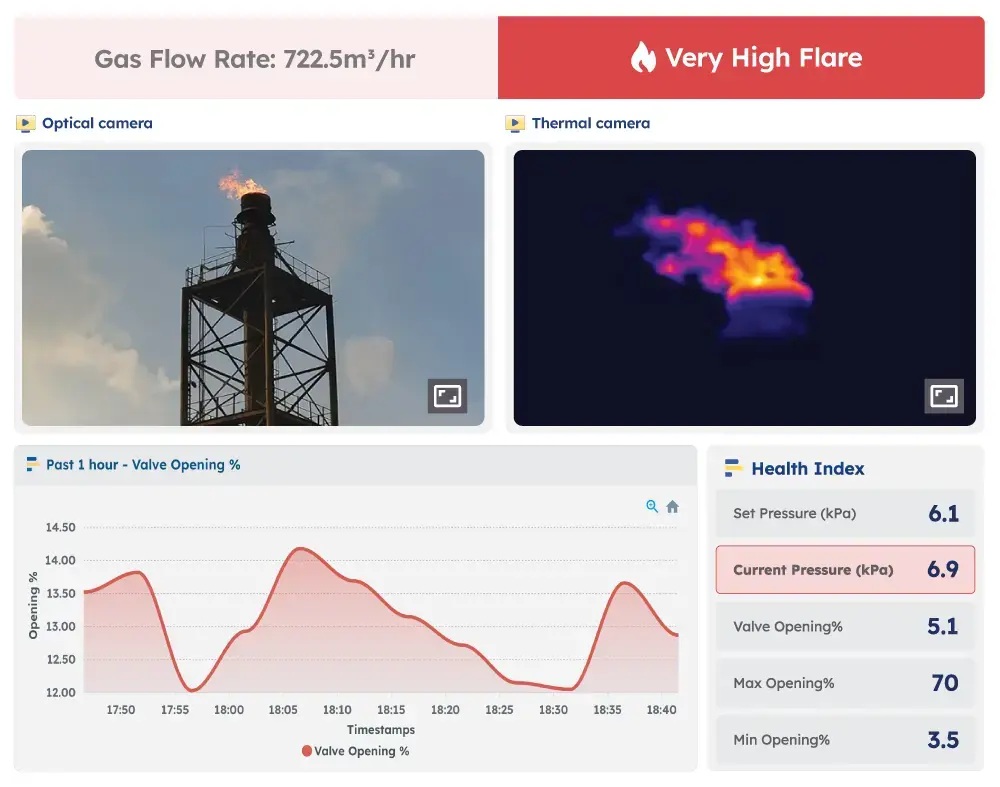

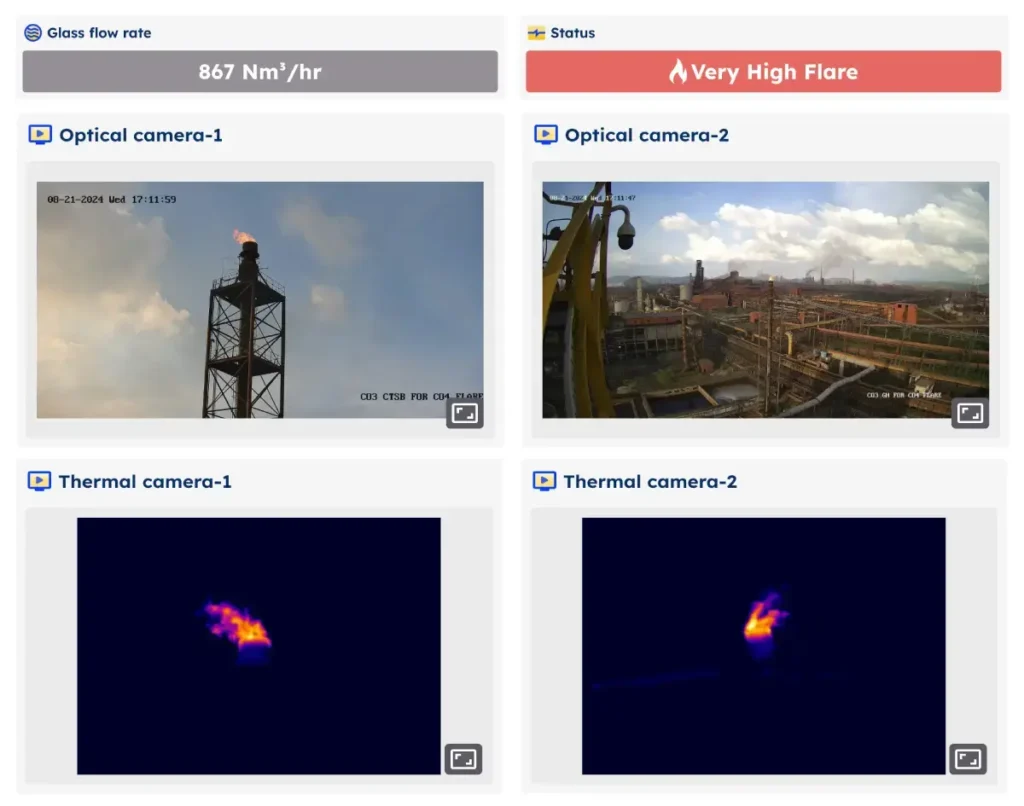

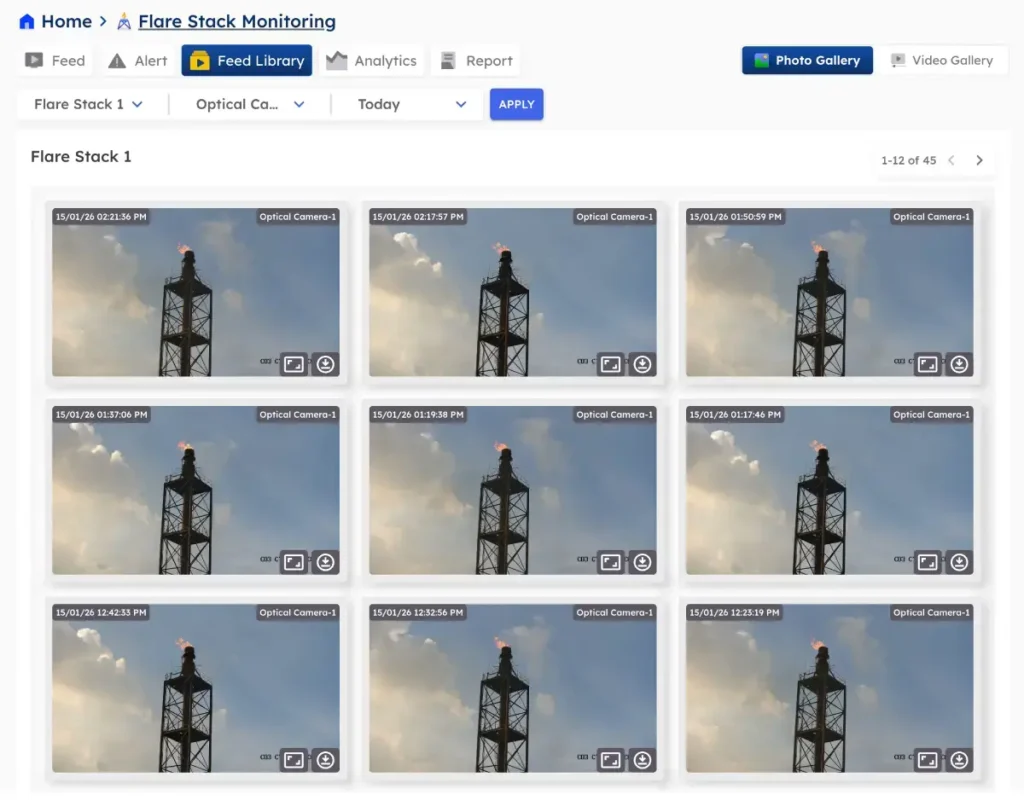

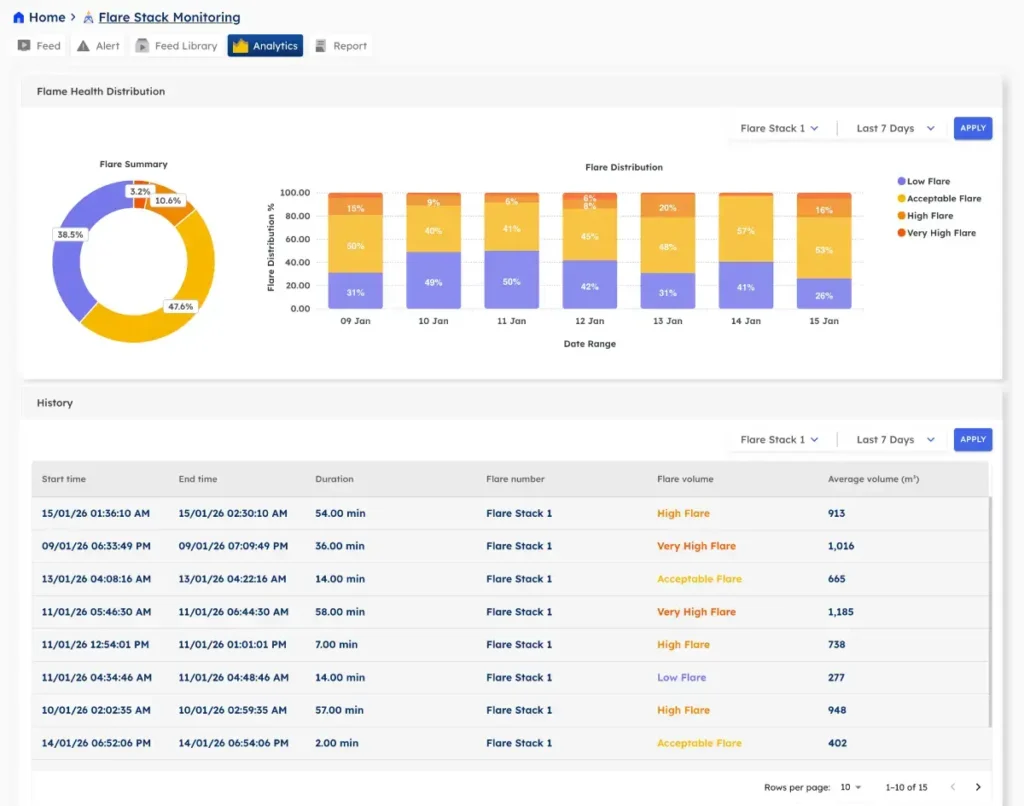

Ripik AI platform for flare stack monitoring system

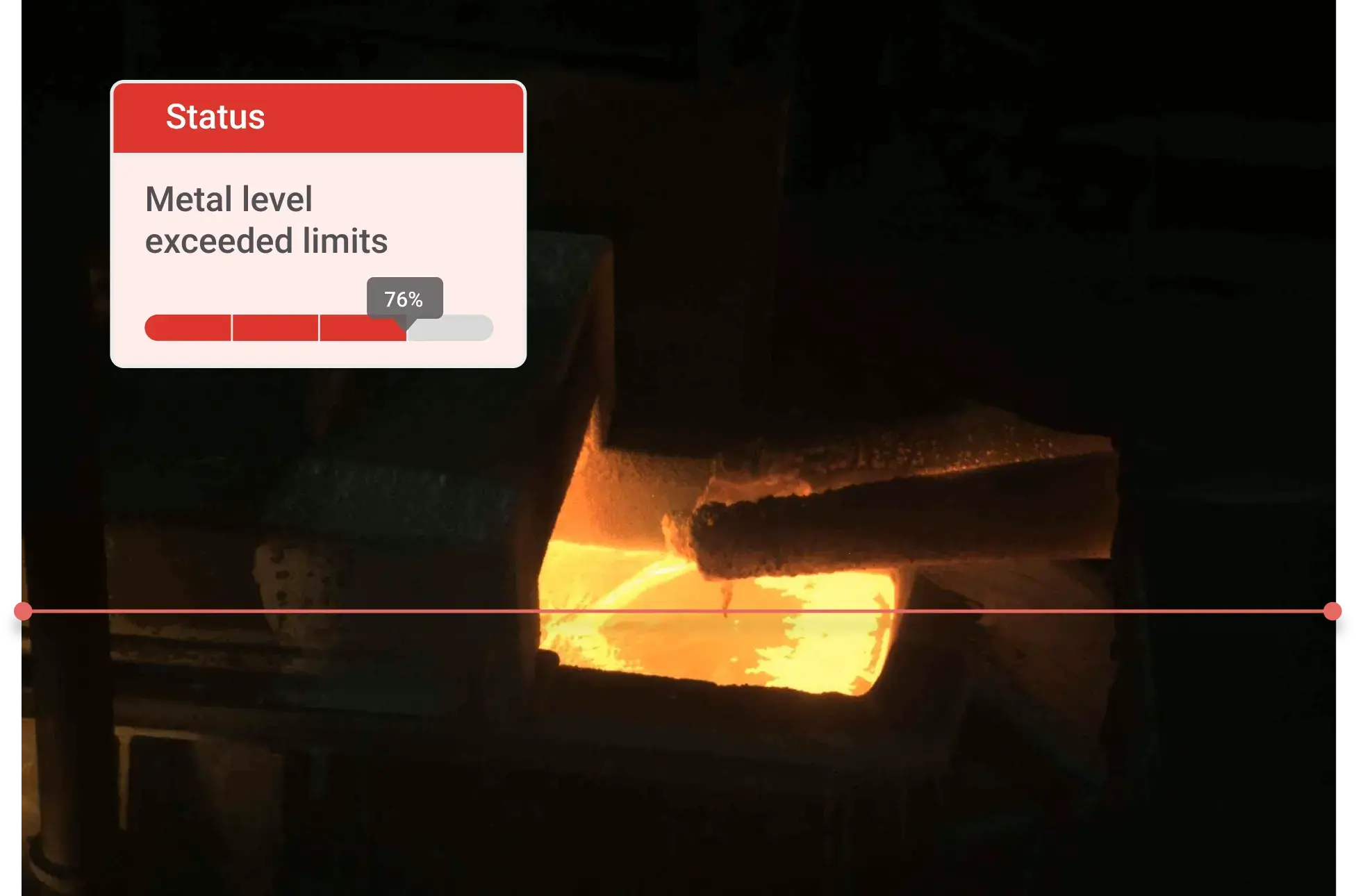

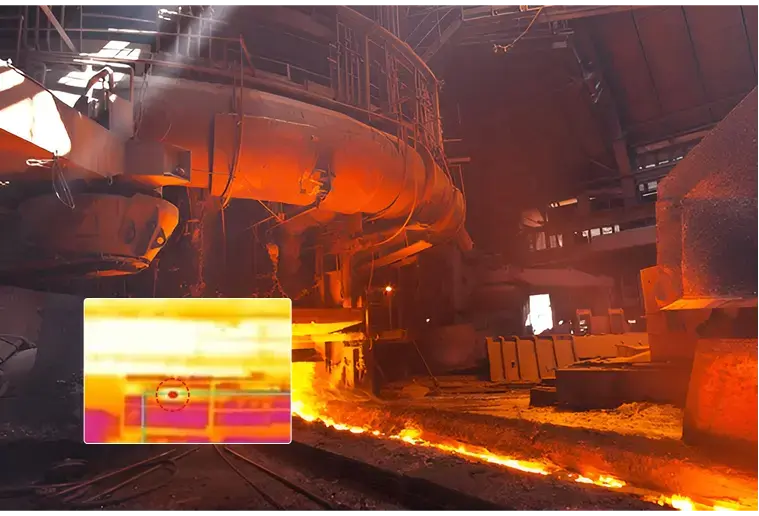

The Ripik AI platform for flare stack monitoring provides 24×7 real-time visibility using advanced infrared and optical vision, AI-driven anomaly detection, and automated alerts, while also developing advanced models for flare monitoring. It enables accurate gas flow measurements through flame–flow correlation, supports combustion efficiency tracking and emissions insights, and offers optional closed-loop controls to improve safety, reduce excess flaring, and ensure regulatory compliance in harsh industrial environments. The system uses combined data from multiple sensors and analytics for improved accuracy in flare monitoring.

Key Features

Real-Time Flare Monitoring

Key Impact of Infrared Flare Monitoring Systems

Reliable flame detection in all conditions, including daylight, smoke, fog, rain, and glare

Real-time detection of flame failure and instability, preventing unburned gas release

Improved combustion efficiency and fuel gas utilization, minimizing black smoke and energy losses

Enhanced operational safety and compliance, lowering fire, explosion, and regulatory risks

Continuous compliance and emissions visibility, supporting regulatory and ESG requirements

Remote, real-time monitoring of flare stacks, reducing manual intervention and response time