AI Platforms for Metal Scrap Inspection

Why is metal scrap inspection is required steel manufacturing?

Steelmaking process has fundamentally changed over the years. Earlier, steel was mainly produced through the blast furnace–oxygen furnace route using iron ore and coke. Now days, a large portion of global steel is produced through Electric Arc Furnace and Induction Furnace technologies, where melting recycled metal scrap from scrap yards, automobiles, appliances, scrap recycling industries and industrial waste streams.

Key Challenges Faced in Scrap Based Steel Production

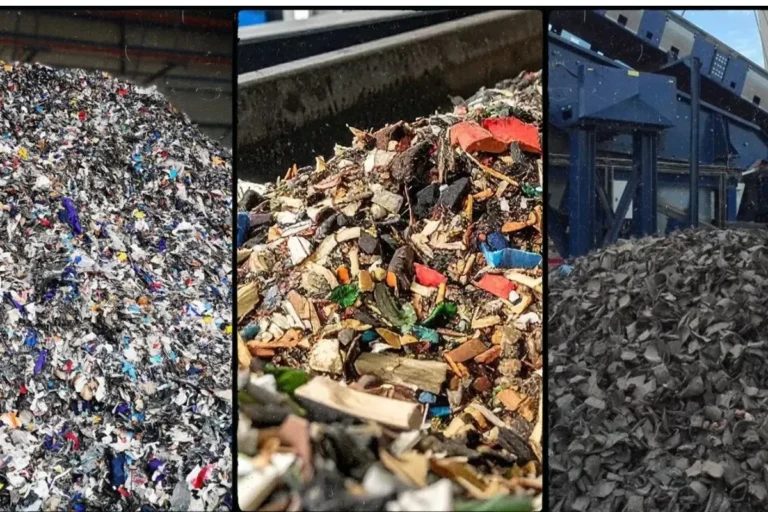

Inconsistent metal scrap composition: Variation metal scrap, such as scrap size, shape, density, and chemical composition, makes furnace behavior unpredictable and difficult to control during melting.

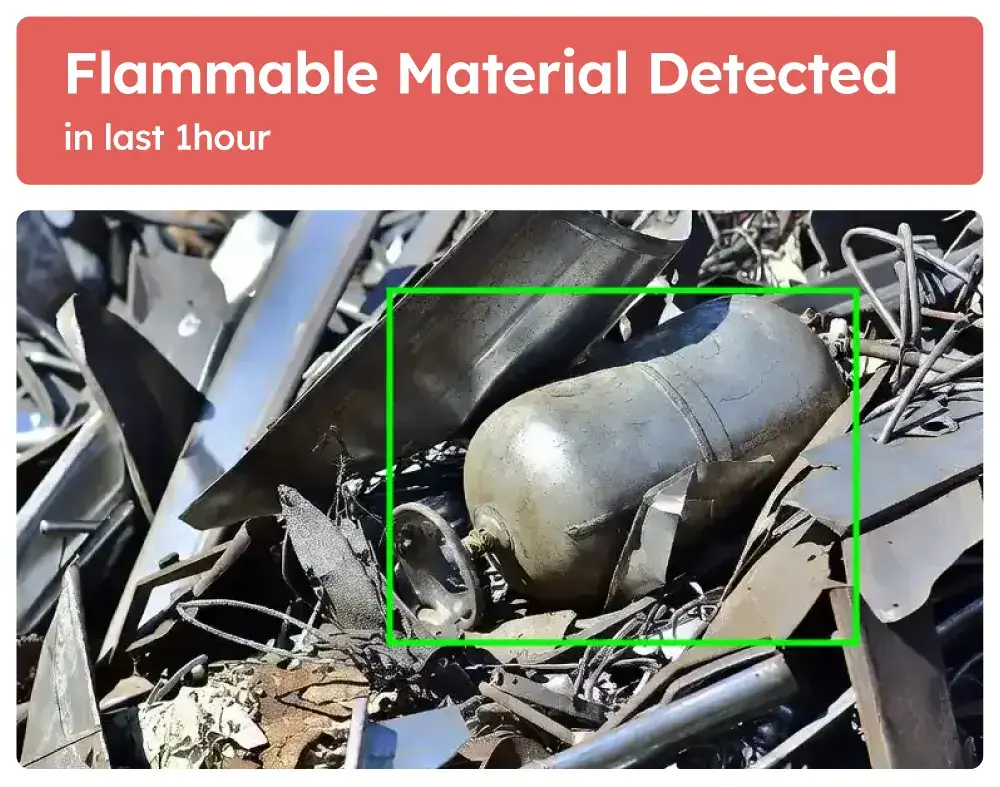

Foreign non Metallic Objects Contamination: Scrap piles often contain non-metallic and hazardous items like batteries, gas cylinders, rubber, plastics, wood, and sealed containers. These pose serious safety risks and can disrupt downstream processes.

Equipment Damage and Downtime: Oversized or improperly processed scrap stresses shredders, conveyors, magnets, and EAF electrodes, causing mechanical failures and unplanned shutdowns.

Ripik AI Platform for Scrap Metal Inspection

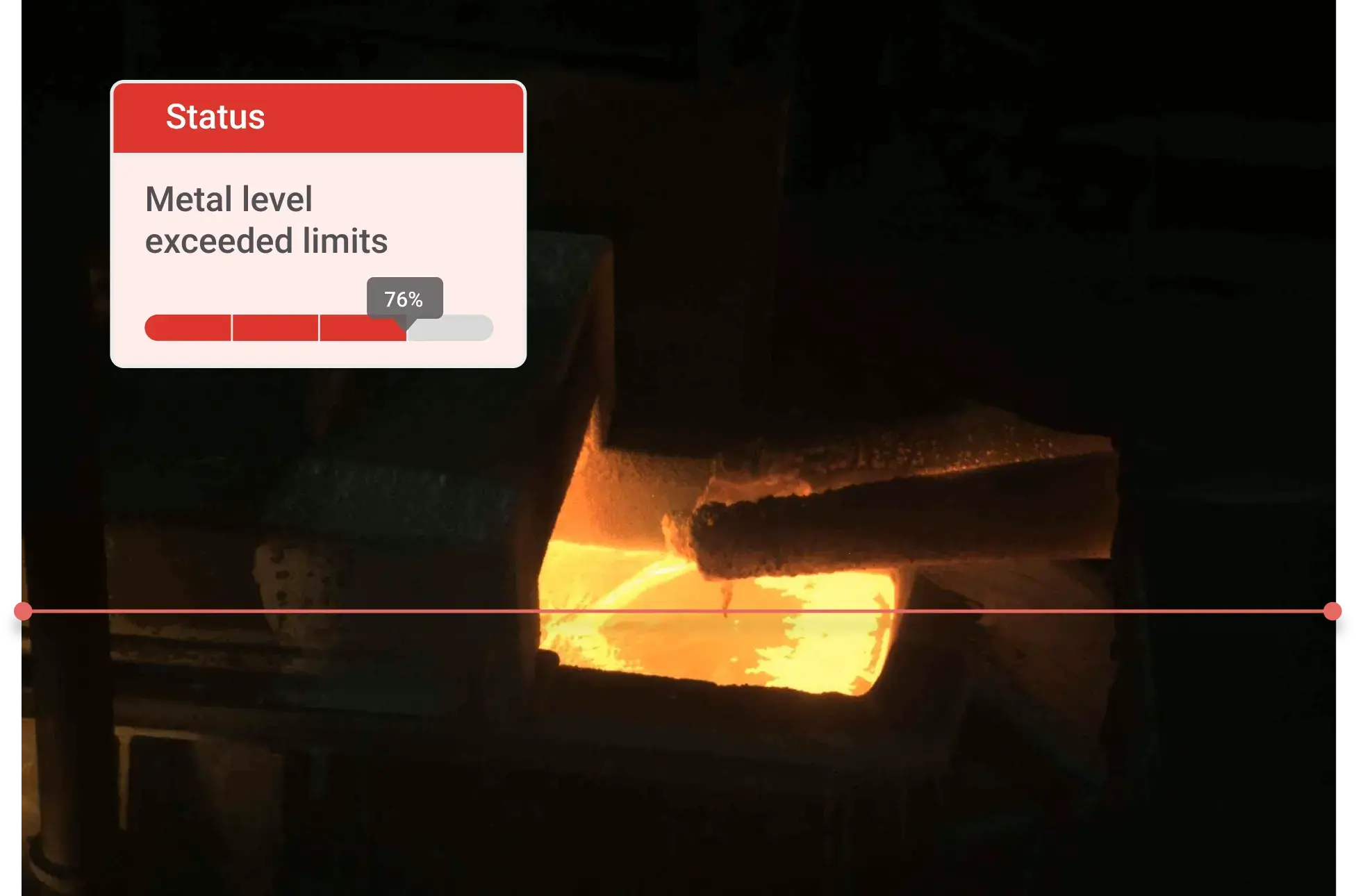

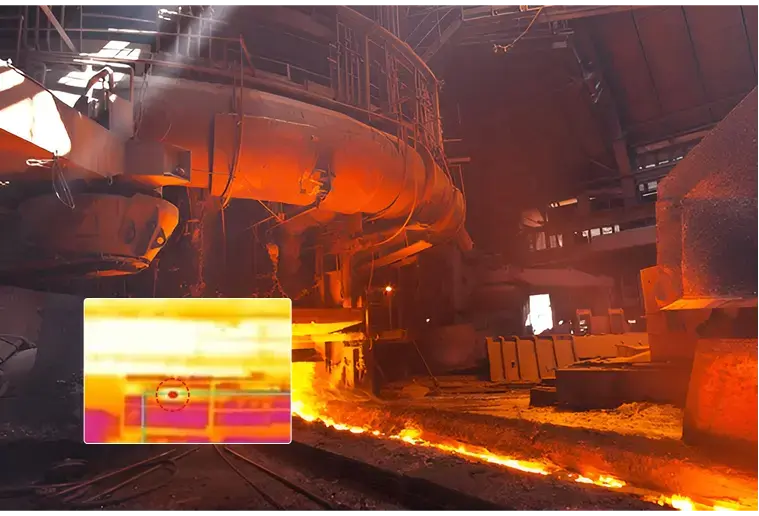

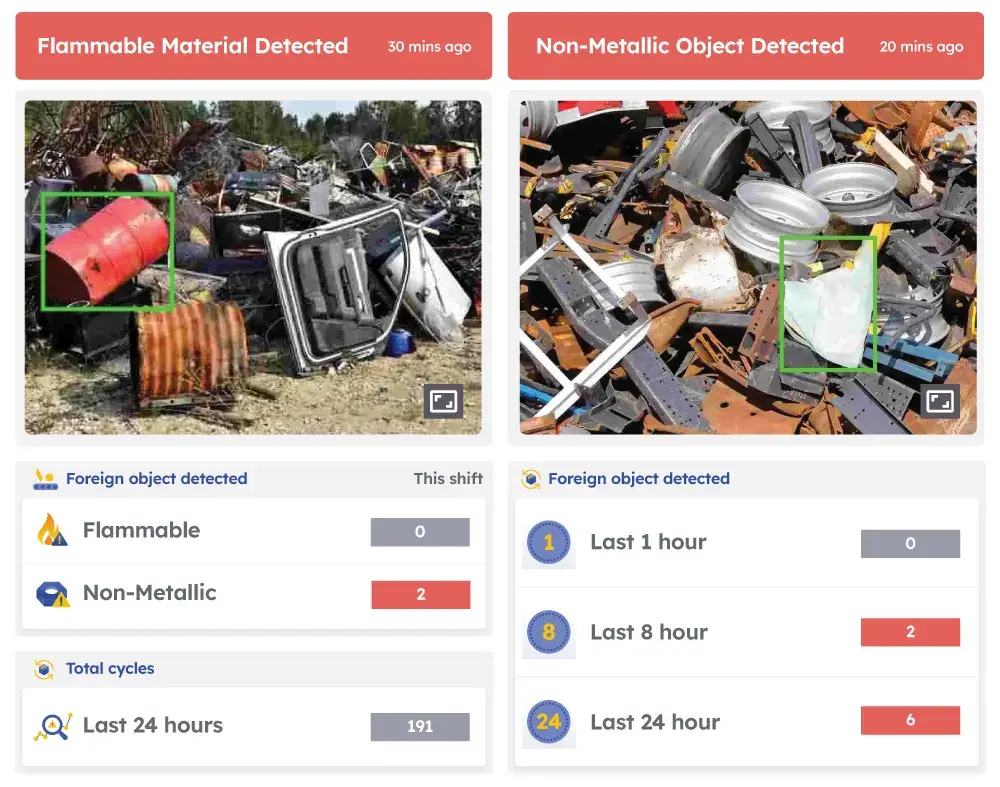

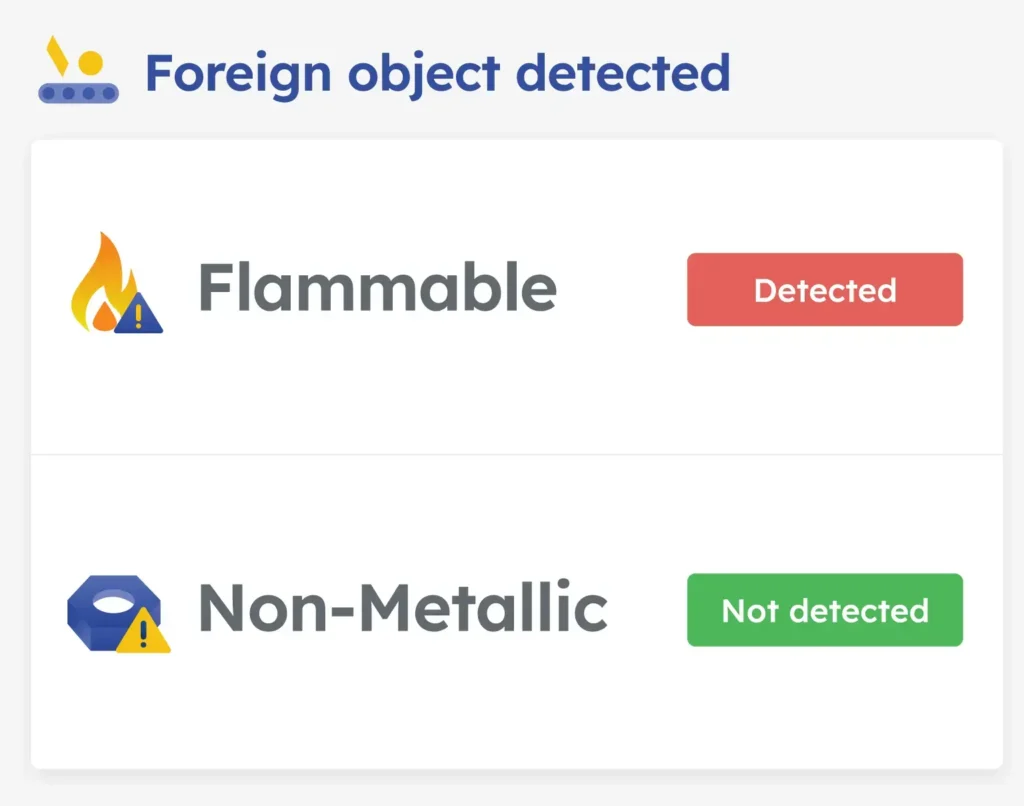

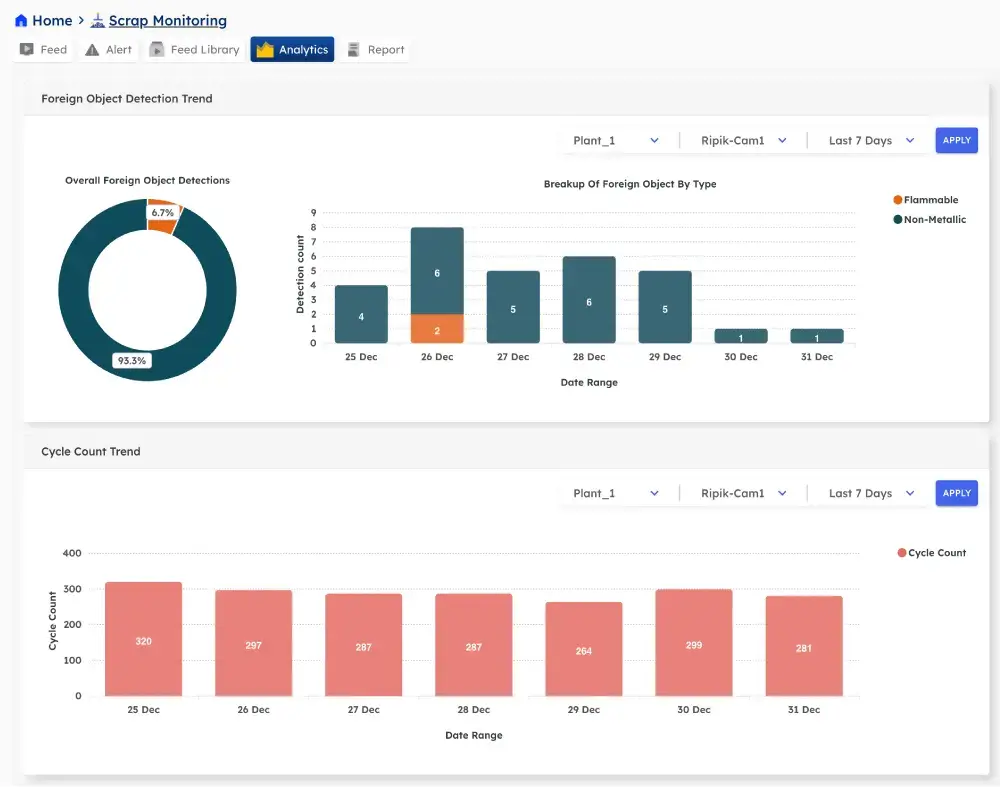

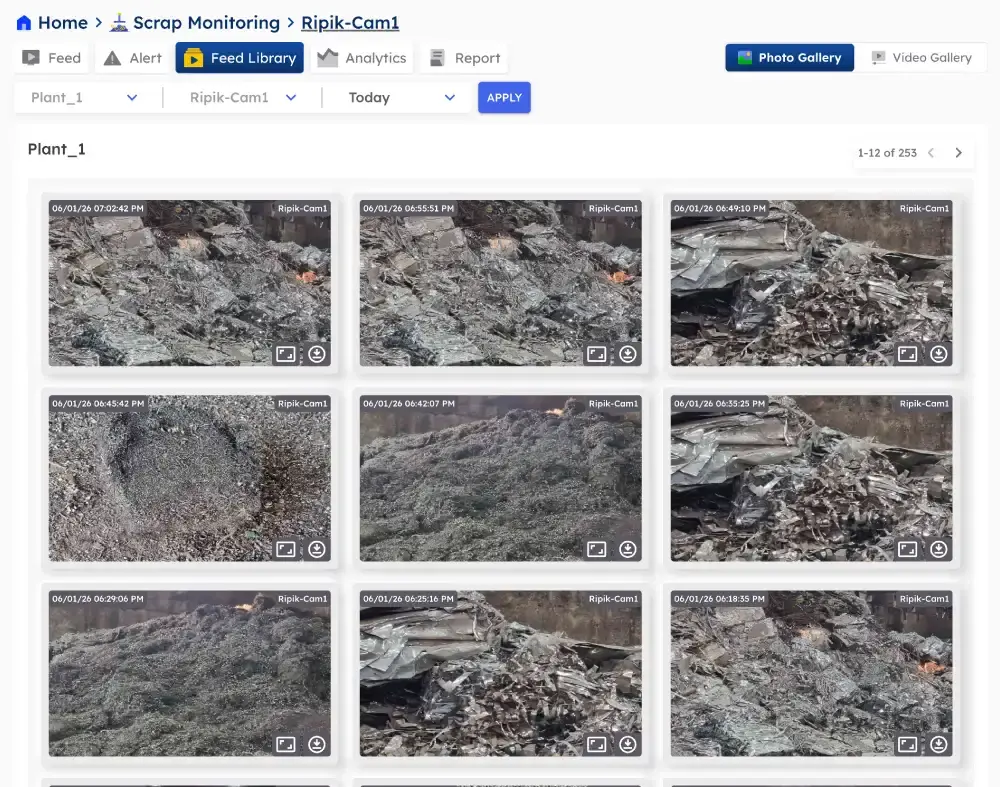

Ripik AI enables real-time steel scrap monitoring of incoming and processed metal from sources such as scrap yards, automobiles, appliances, metal recycling industry and industrial waste streams used in the steelmaking process. The scrap metal inspection automatically inspects scrap for size, shape, density, and contamination to identify dangerous materials and oversized pieces before they reach critical operations. Hazardous items like batteries, gas cylinders, and pressurized canisters are detected early, and instant alerts are sent to the concerned teams. This proactive approach helps prevent accidents, protects vital assets including furnace components and conveyors, and ensures smooth, stable, and consistent steel production.

Key Features

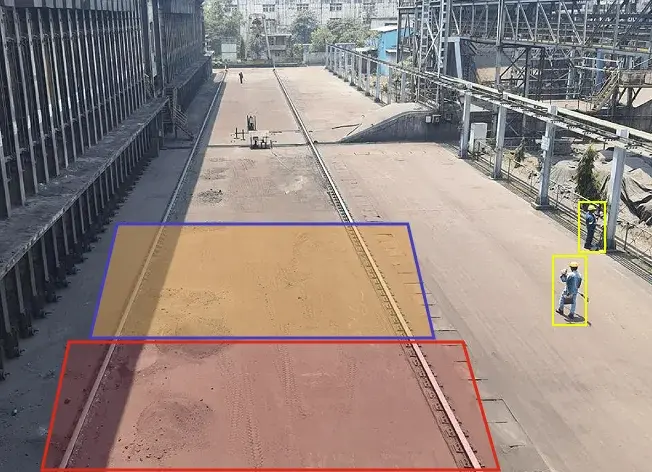

Real-time Steel Scrap Monitoring

Large Particle and Foreign Object Detection

Key Impact of Scrap Inspection Platform in Steel Manufacturing

- Fewer accidents and explosions through systematic early detection of hazardous and non-compliant scrap

- Reduced unplanned downtime by eliminating process interruptions before furnace charging

- Protection of costly equipment including electrodes, conveyors, and shredders from oversized and foreign materials

- Stable melts and improved yield with better control over scrap quality and heat chemistry

- Data-driven process improvement enabled by real-time visibility, analytics, and actionable intelligence