AI for Slag Detection

What is Slag?

Slag is a non-metallic byproduct generated during various stages of steelmaking, such as in the Blast Furnace (BF), Basic Oxygen Furnace (BOF), Electric Arc Furnace (EAF), converter, ladle, and many more. It forms when impurities from raw materials — including silica, alumina, phosphorus, sulfur, and ash — combine with fluxes like lime. This mixture floats on top of the molten steel because of its lower density, creating a separation layer between pure hot metal and impurities.

Why Is a Slag level Detection is Important in Steel Plants?

Slag level detection is critical in steel plants because it ensures cleaner steel, safer operations, and more efficient tapping. Accurate monitoring of the transition between slag and steel is essential for process control.

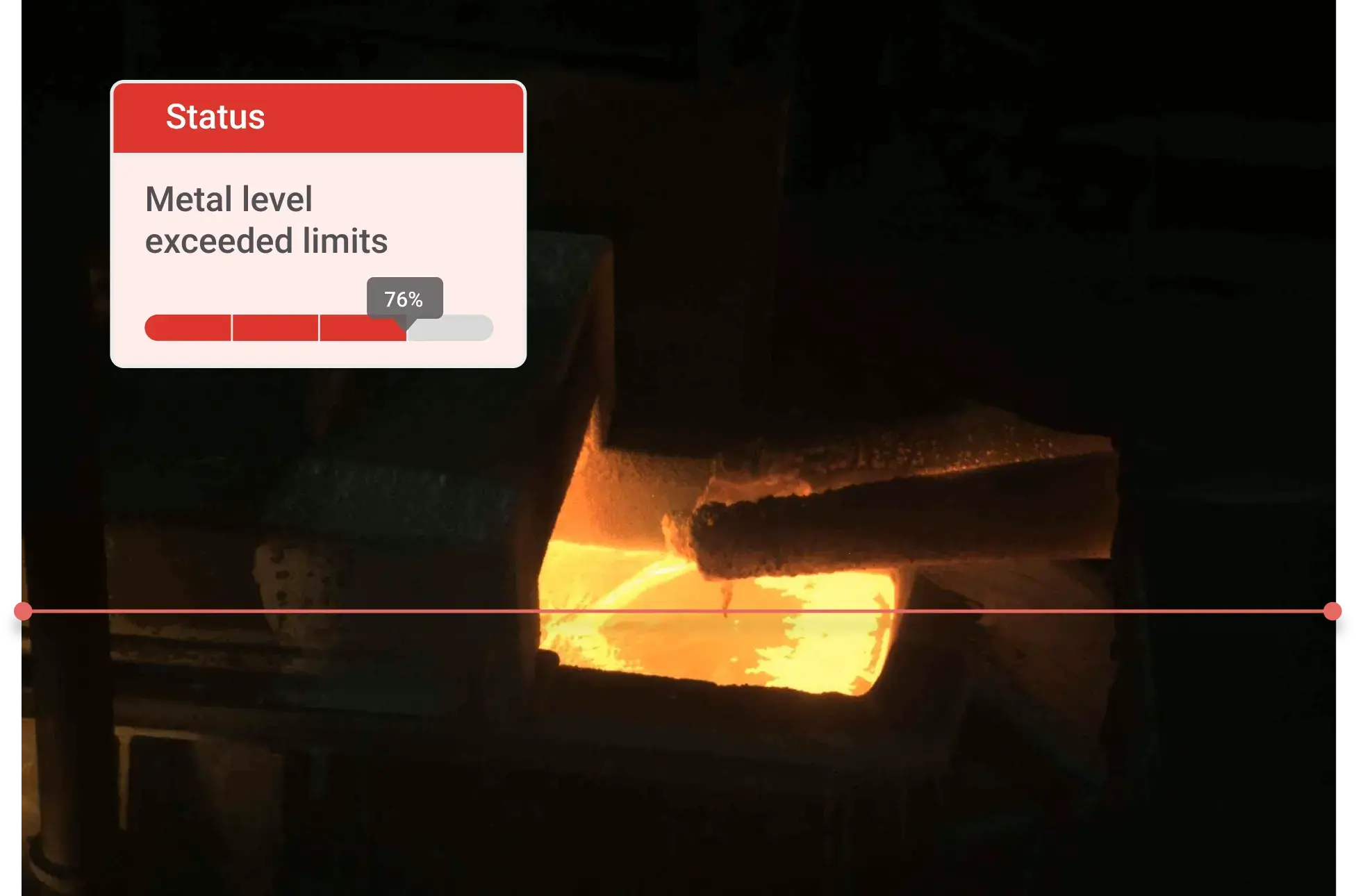

When slag levels are not monitored accurately, slag carryover can contaminate molten steel, increase defect rates, and raise refining costs. It also accelerates refractory wear, reducing equipment life and causing more frequent shutdowns. Additionally, inaccurate molten metal level readings increase the risk of overflows, bursts, and splashes—leading to safety hazards, equipment damage, and unplanned production stoppages. Reducing operator intervention through automated monitoring improves safety and efficiency.

Accurate slag level detection helps maintain process stability, reduce losses, and improve overall operational reliability. The advantages and benefits of slag level detection for the steel industry include supporting the ongoing process, meeting the increasing demand for high-quality steel, and ensuring safer, more efficient, and reliable operations.

Key Reasons:

Ensures cleaner steel and better product quality by preventing slag carryover and reducing defects.

Reduces operational costs by lowering refining needs, alloy corrections, minimizing hot metal losses, and reducing maintenance requirements.

Protects equipment and refractories, reducing corrosion, extending furnace life, and preventing damage from overflows or splashes.

Improves operational stability by avoiding unplanned stoppages and ensuring safer, more consistent tapping operations.

Customers benefit from improved reliability and reduced maintenance needs, ensuring efficient and dependable slag detection solutions.

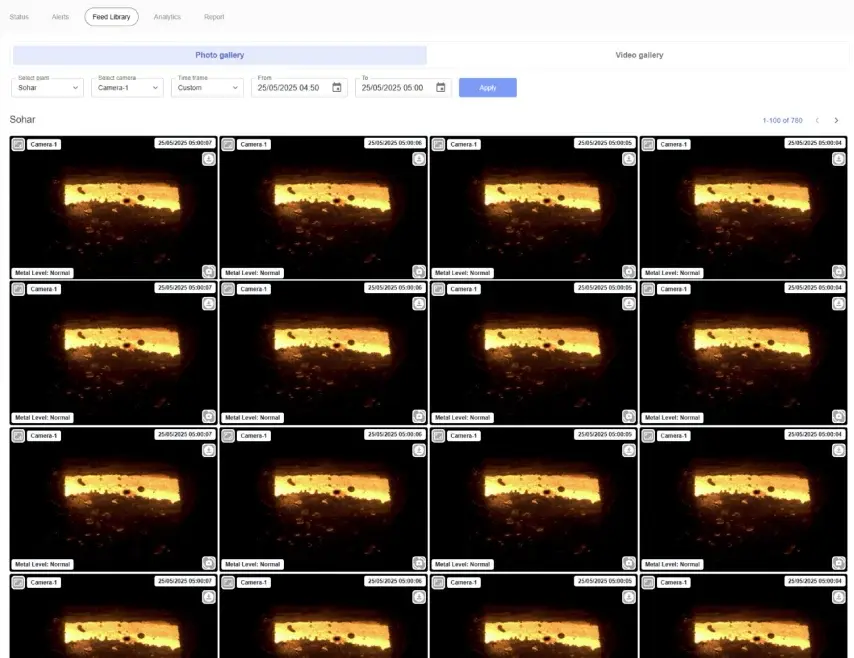

Ripik AI Platform for Slag Level Monitoring System

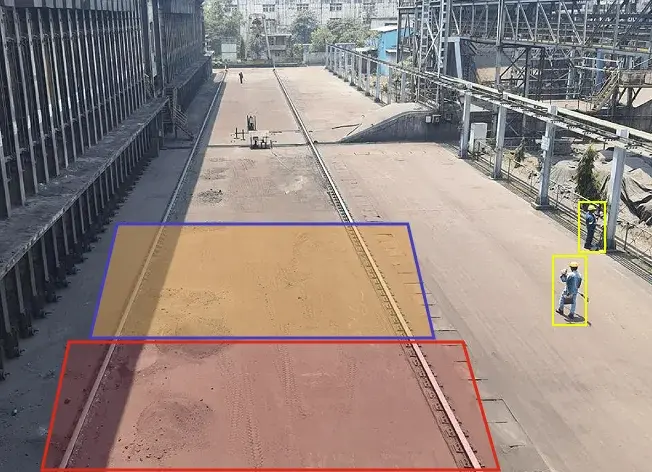

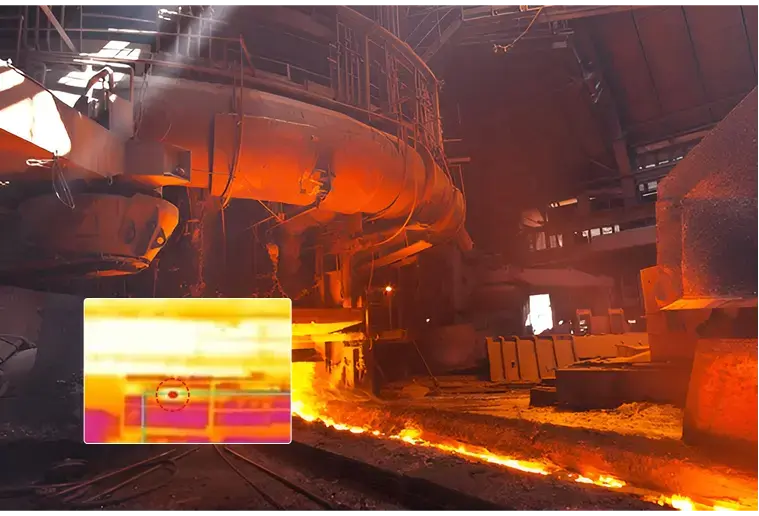

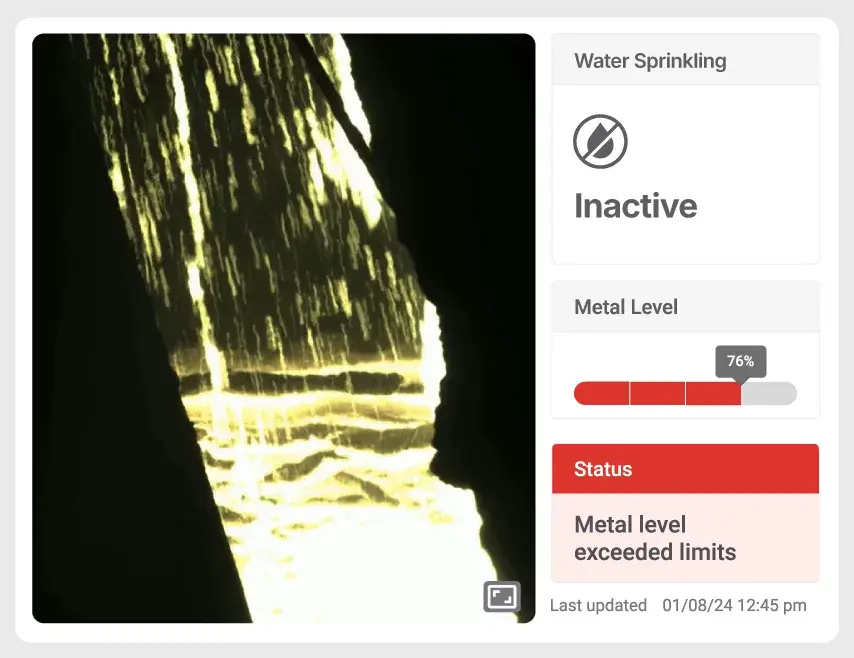

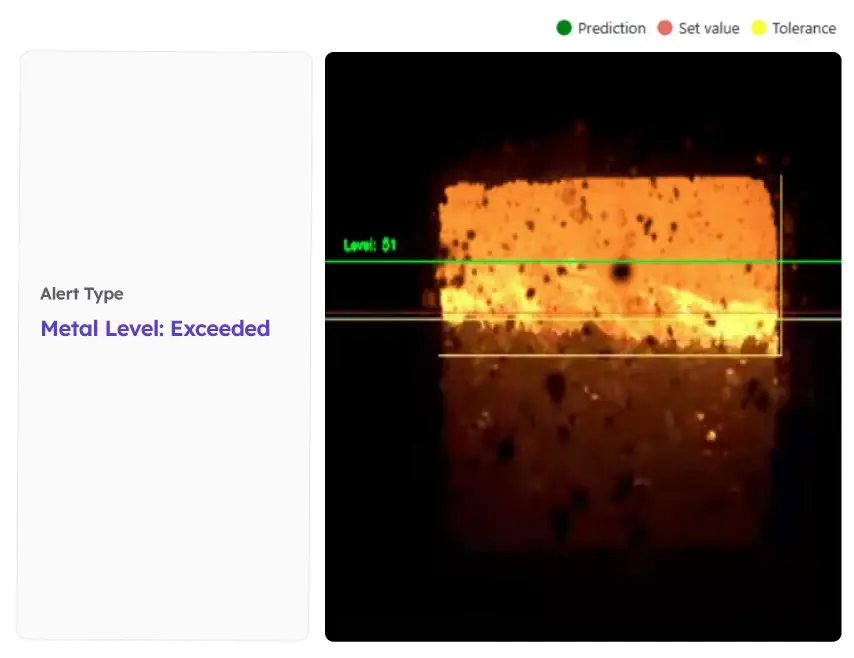

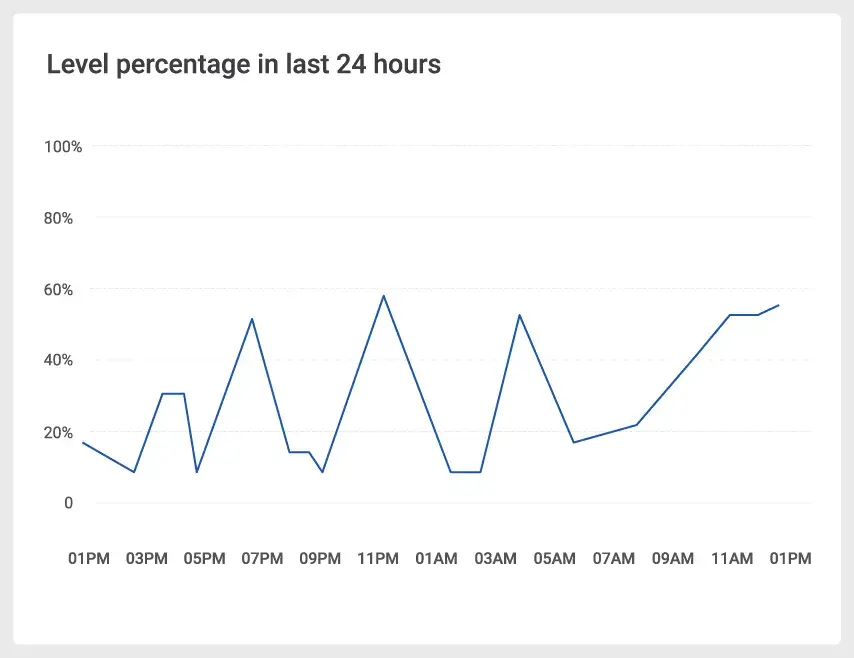

Ripik AI offers an advanced, AI-driven slag monitoring system that combines real-time slag level detection with programmable closed-loop water-sprinkler control, triggering instant alerts whenever levels exceed safe thresholds or automatically reduce inflow when required. Powered by cutting-edge computer vision, thermal imaging, and machine-learning analytics, it provides highly accurate image- and video-based slag identification even in challenging steel plant environments with smoke, dust, vibration, and fluctuating lighting. The system continuously monitors tapping conditions across EAF, BOF, and AOD operations to prevent unsafe situations, protect equipment, improve yield, and significantly reduce slag carryover.

Key Features

Real-time Slag Monitoring

Closed-Loop Water-Sprinkler Control

Key Impact of Steel Slag Detection System

Cleaner Steel Quality:Prevents slag carryover, reducing impurities and improving final product quality.

Higher Yield: Minimizes metal losses trapped in slag and ensures optimal tapping accuracy.

Lower Operational Costs: Cuts down on extra refining, alloy corrections, and reprocessing due to slag contamination.

Enhanced Equipment Life: Reduces refractory and tap-hole damage caused by corrosive slag.

Improved Plant Safety: Avoids overflows, splashes, and unsafe tapping conditions through precise real-time monitoring.

Stable and Consistent Operations: Standardizes tapping practices, minimizes human error, and improves furnace process stability.

Reduced Downtime: Prevents unplanned stoppages and equipment failures linked to poor slag control.

Better Decision-Making: Provides actionable insights, trends, and alerts for continuous improvement and operational optimization