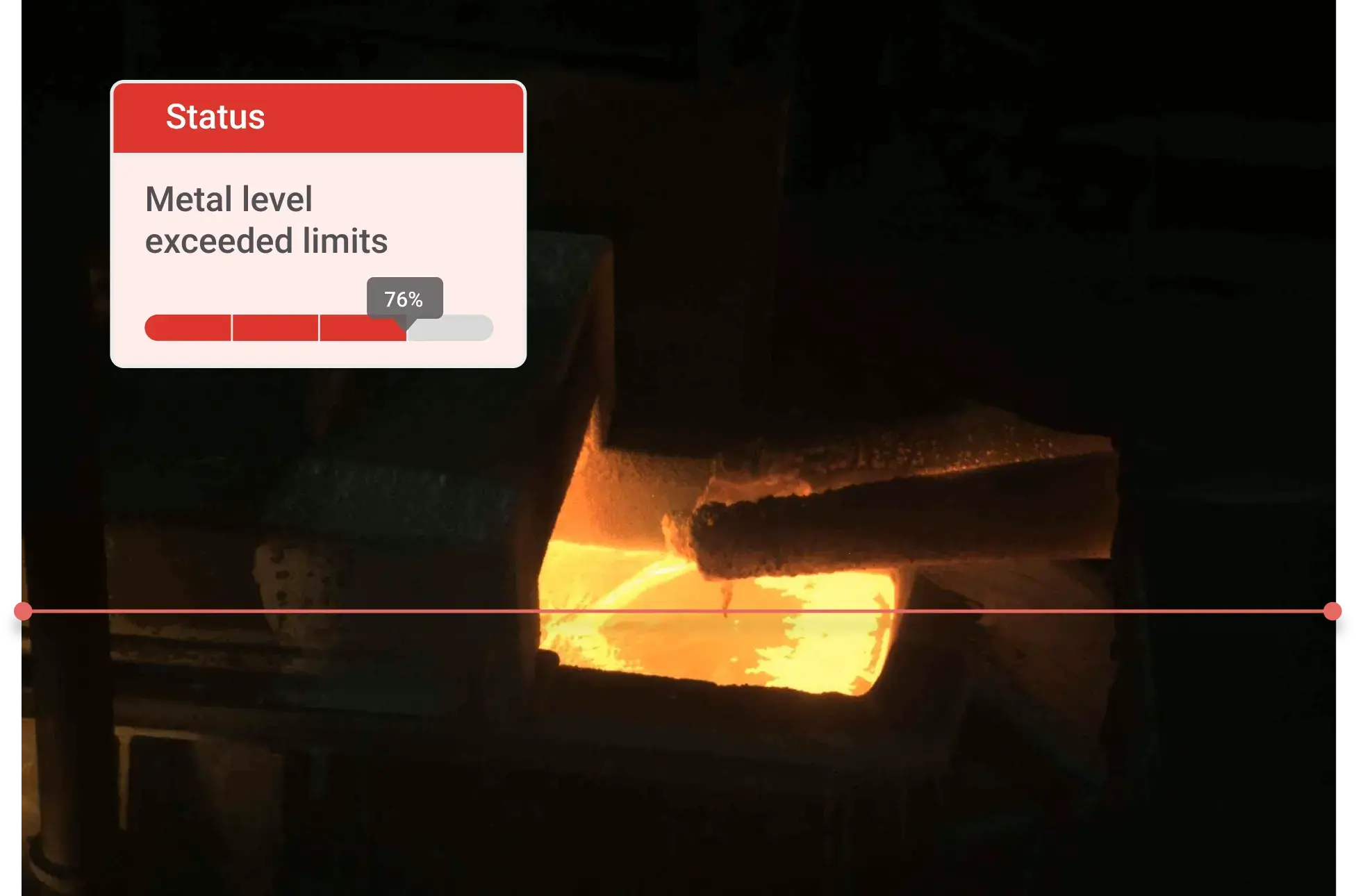

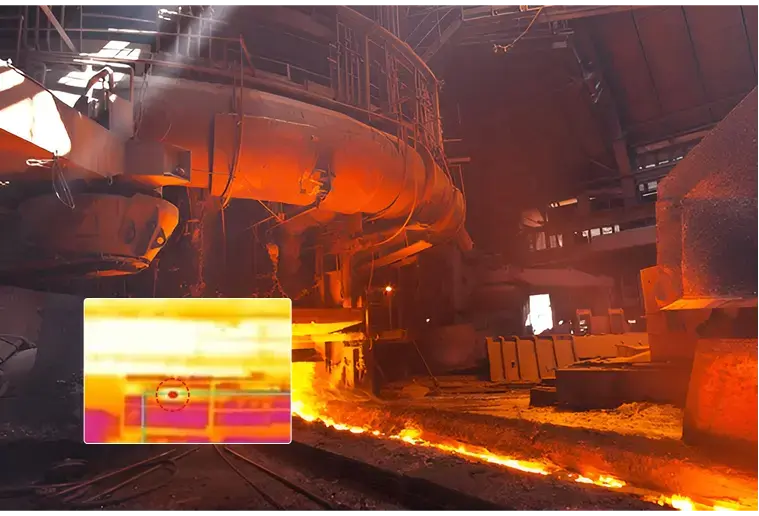

Accurate molten metal level measurement is vital for maintaining stability, safety, and quality in modern steel plants. Even small variations in molten steel levels can cause overflows, product defects, and higher energy use.

Why Calorific Value Estimation of Alternate Fuels Matters in Cement Production Introduction Cement manufacturing is inherently energy-intensive, with thermal energy accounting for nearly 40% of total production costs. The kiln—the heart of every cement plant—operates at temperatures above 1,450°C, requiring consistent heat input to ensure uniform clinker formation and process efficiency. Any fluctuation in fuel […]

In heavy industries such as cement, steel, and mining, where conveyor systems are the backbone of material handling, even a single conveyor breakdown can cost millions in lost production.

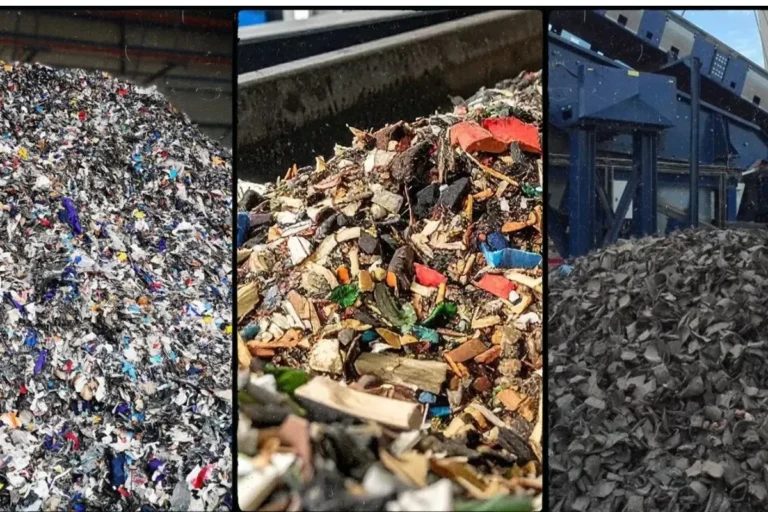

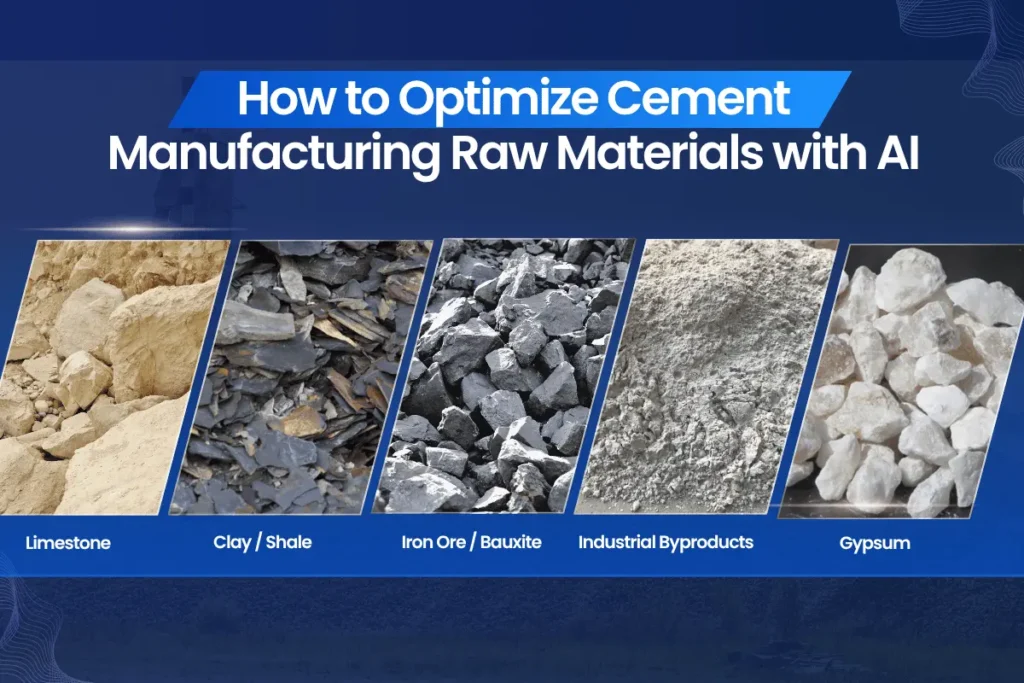

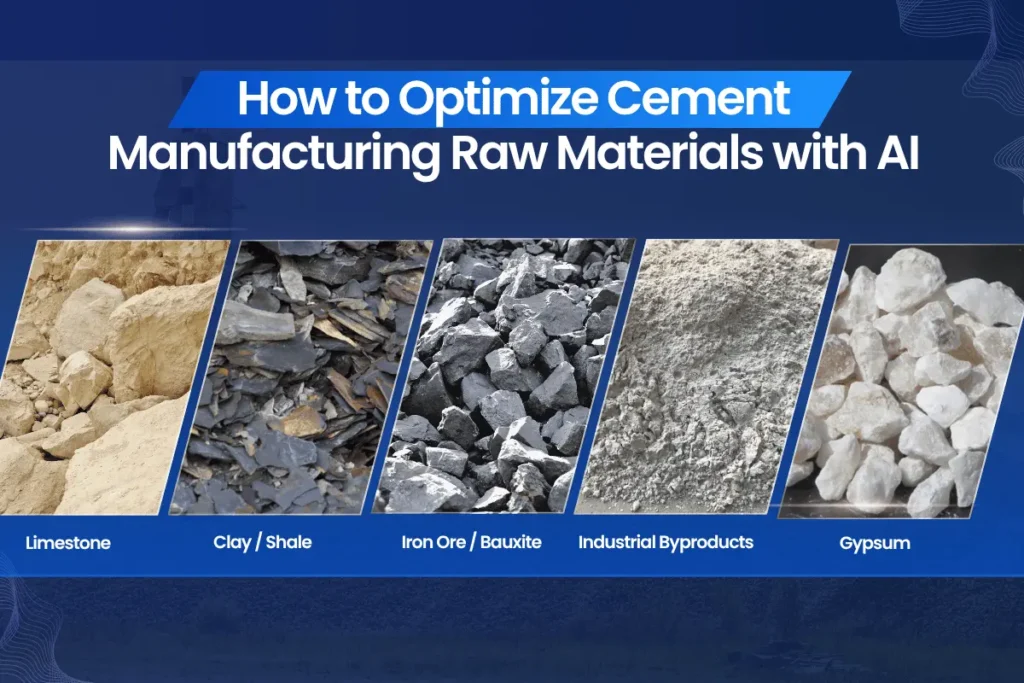

AI is transforming cement raw material management by monitoring quality, moisture, and composition in real time, ensuring precise handling, consistent feeding, and optimized clinker production.

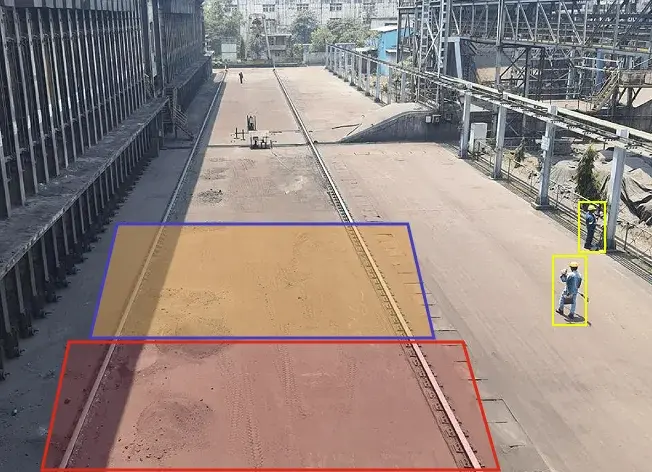

Computer vision is a branch of artificial intelligence (AI) that enables machines to interpret, analyze, and understand visual data from images, videos, and other visual inputs.

AI Applications in Manufacturing: Improving Efficiency, Quality, and Safety. Introduction The manufacturing industry is undergoing a rapid digital transformation, with Artificial Intelligence (AI) at the core of this change. The integration of AI applications in the manufacturing industry is helping companies streamline operations, optimize supply chains, and achieve higher levels of efficiency across the value […]

AI-Driven Productivity Tracking involves real-time monitoring of workflows, resources, machine performance, automated systems, and processes to enhance operational efficiency.

IR monitoring combined with vision systems are trained to identify complex patterns and subtle thermal anomalies within the infrared spectrum, such as uneven heating in refractories or developing hot spots in ladles used for molten metal handling. Early detection of issues like cracks, lining erosion, or overheating helps prevent costly equipment failures.

Machine health monitoring empowers maintenance teams to transition from reactive maintenance to condition-based maintenance significantly improving asset performance and reducing maintenance costs.

As businesses scale and diversify, the demand for greater efficiency, minimal downtime, and enhanced safety has driven the need for advanced monitoring agents to unlock new levels of productivity, safety, and operational efficiency across sectors.