Need of blast furnace in steel industry

Understanding Blast Furnace Operations

How does the Blast Furnace Works?

Charging: Introduction of Raw Materials

Combustion Zone: Coke Ignition to Generate High Temperatures

Reduction Reaction: Iron Ore Reduction to Molten Iron

Slag Formation: Separation of Impurities as Slag

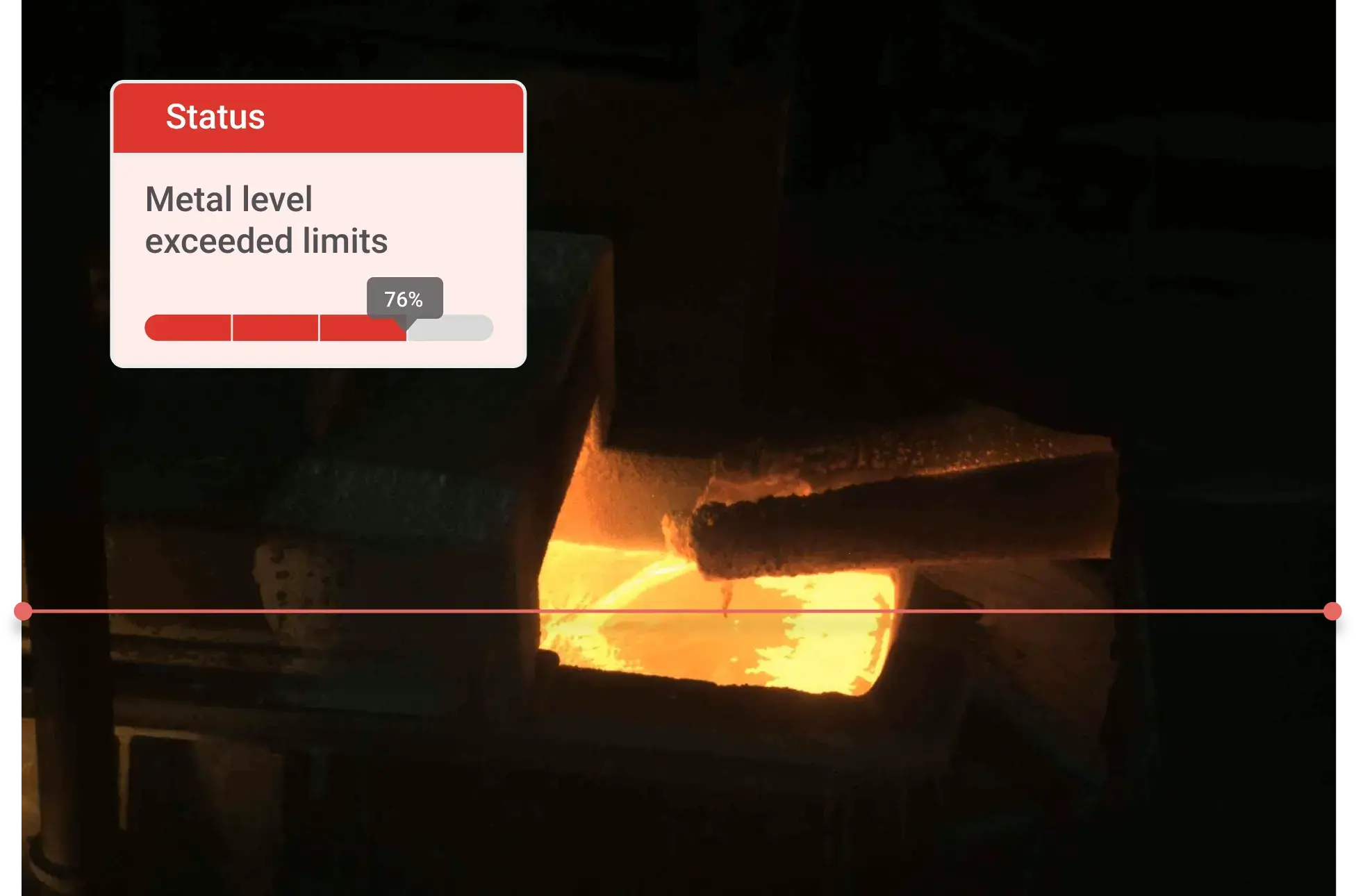

Tapping Process: Extraction of Molten Iron and Slag

Blast Furnace vs Electric Arc Furnaces: Understanding the Differences in Steel Production

The Blast Furnace Process

The Electric Arc Furnace (EAF) Process

Common Challenges in Blast Furnace Operations

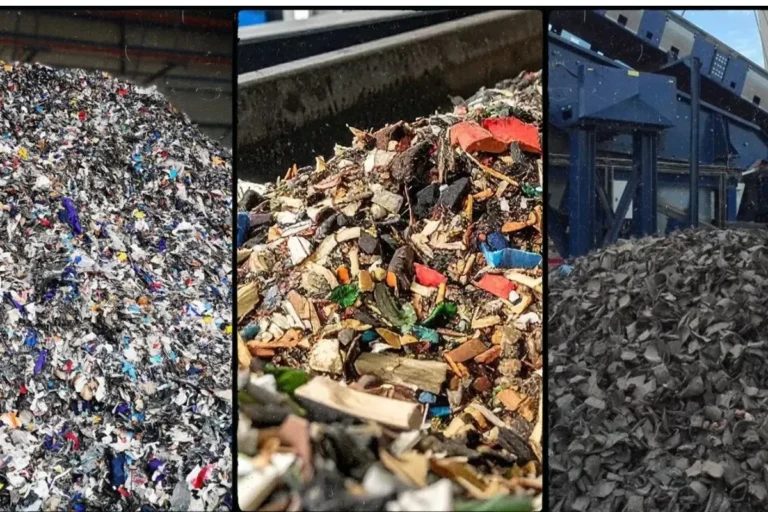

Inconsistent Raw Material

Temperature Fluctuations

Inefficient Burden Distribution

Uncontrolled slag viscosity

Fuel Inefficiency

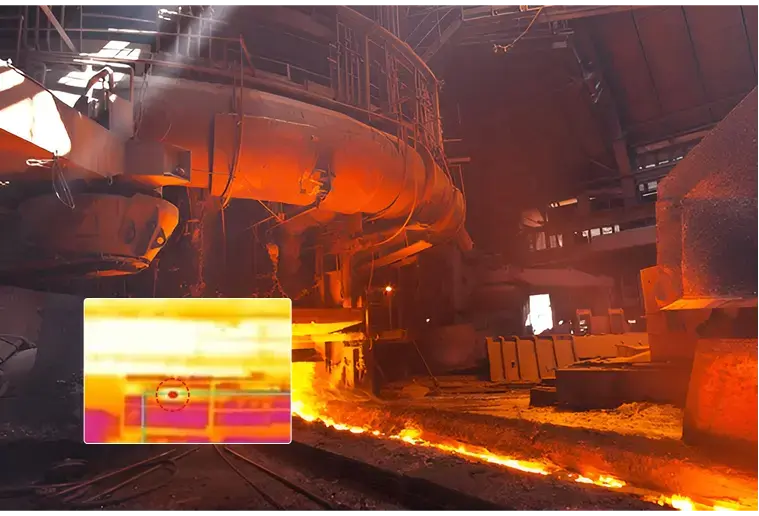

Refractory Wear and Tear

High Carbon Emissions

The Role of AI in Blast Furnace Steel Making Process

Real-Time Monitoring: AI-powered computer vision systems enable real-time monitoring of blast furnaces. By tracking critical factors like temperature, pressure, and chemical reactions, AI provides valuable insights into the furnace’s current state. This enables operators to make informed decisions promptly and ensures the process stays within optimal conditions, improving efficiency and safety.

Early Warning Alerts: Vision AI tools allows early detection of anomalies within the furnace. With its ability to detect issues such as tuyere blockages, lance misalignment, or raceway instability, computer vision systems provides early warning alerts that allow operators to address problems before they escalate.

Historical Data Analysis: Vision AI tools analyze historical data to uncover patterns and trends, offering deeper insights into furnace behavior. By processing visual data, AI identifies recurring issues, temperature fluctuations, and chemical imbalances, enabling proactive adjustments and improving furnace efficiency.

Predictive Analytics: AI in computer vision solution utilizes predictive analytics to forecast potential deviations in furnace stability. By analyzing historical data and recognizing patterns, AI can anticipate issues such as temperature fluctuations, pressure changes, or chemical imbalances. This allows for proactive adjustments to prevent costly downtimes and maintain smooth furnace operations.

Process Automation: AI systems significantly contribute to automating various aspects of the blast furnace process. By optimizing fuel injection, air control, and charge material ratios, Vision AI tools ensures these critical elements are managed efficiently and accurately. This automation reduces human error, enhances process consistency, and leads to more efficient fuel usage, ultimately cutting operational costs.

Automated Root Cause Analysis (RCA): When issues arise in the blast furnace, AI helps by performing automated root cause analysis (RCA). AI systems analyze data across multiple variables to pinpoint the underlying factors impacting key performance indicators (KPIs). With this precise analysis, operators can quickly implement corrective actions, improving overall furnace efficiency and production quality.

Vision AI applications in Blast Furnace Operations

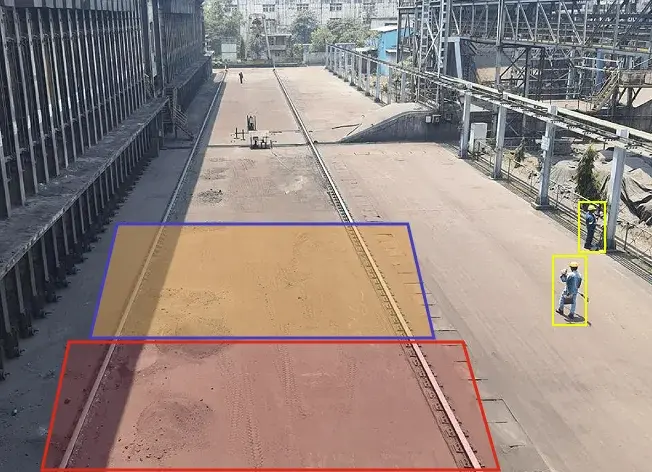

Real-time raw material sizing

Burden Distribution optimization

RCA module for etaCO

Tuyere Monitoring

Hot Metal Silicon Prediction Module

Furnace Refractory Monitoring

Bunker level Monitoring

Impact of AI in Blast Furnace Operation for steel manufacturing process

Real-Time Monitoring and Insights

Optimized Burden Mix and Distribution

Predictive Maintenance in Steel Plants

Blast Furnaces Process Optimization

Improved Product Quality

Enhanced Safety

Conclusion