What is Asset Performance Management?

What is Asset Performance Management System?

Components of an Asset Performance Management Solution

Real-Time Machine Monitoring and Data Collection

Predictive Analytics

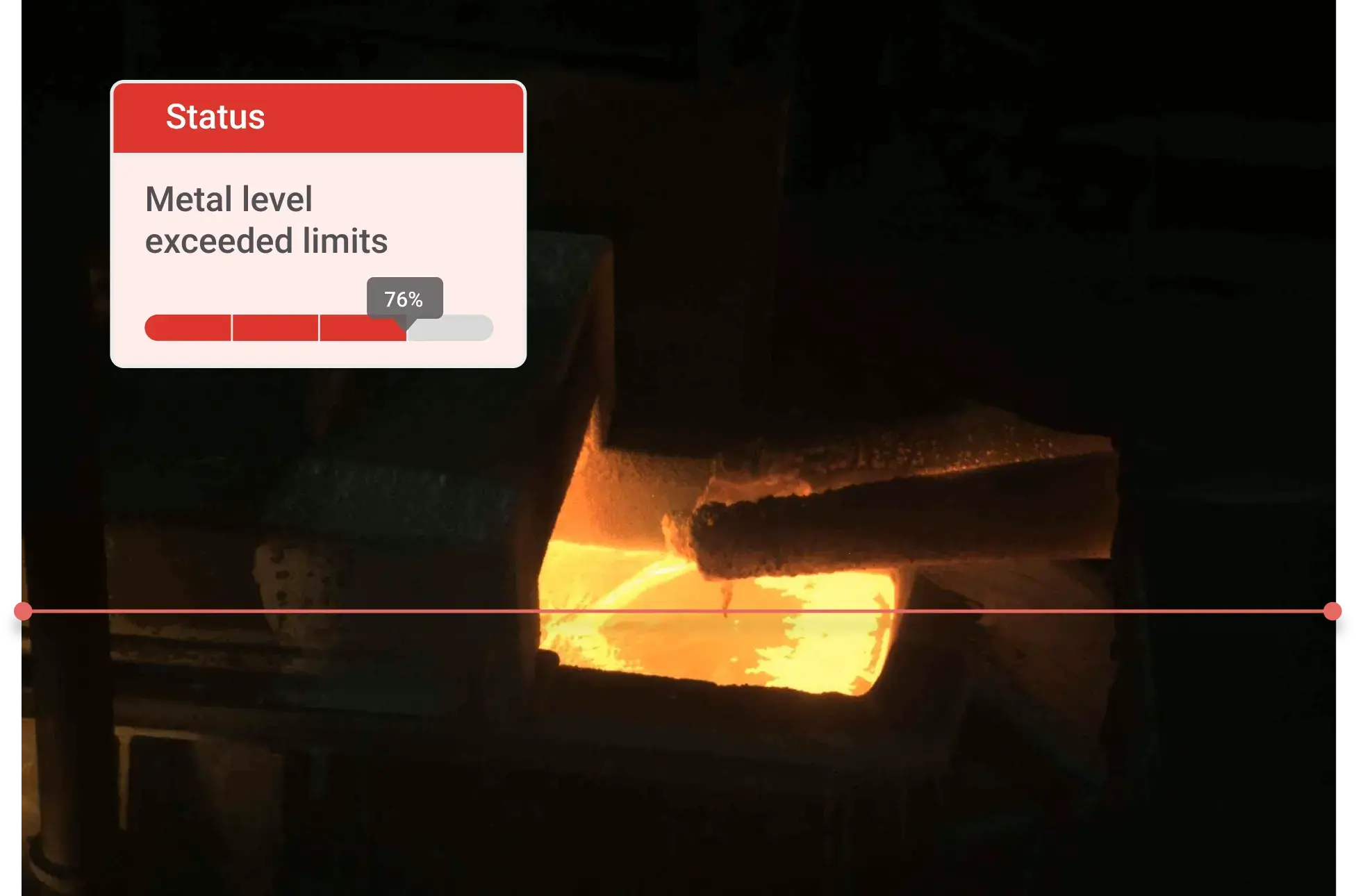

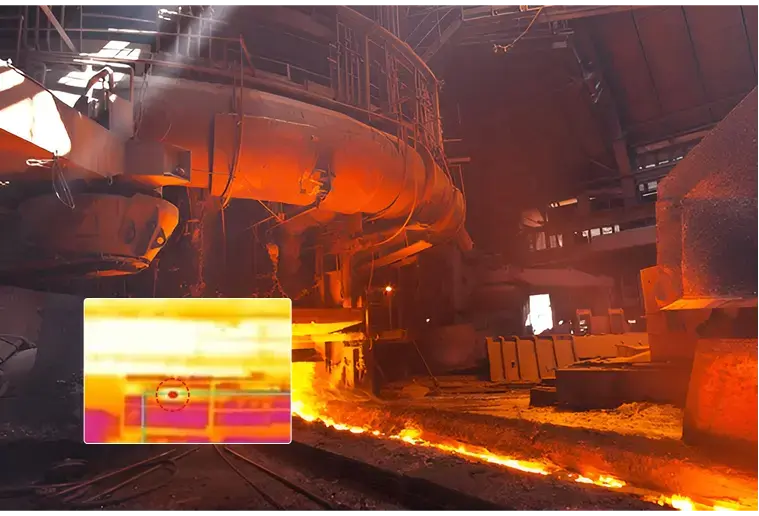

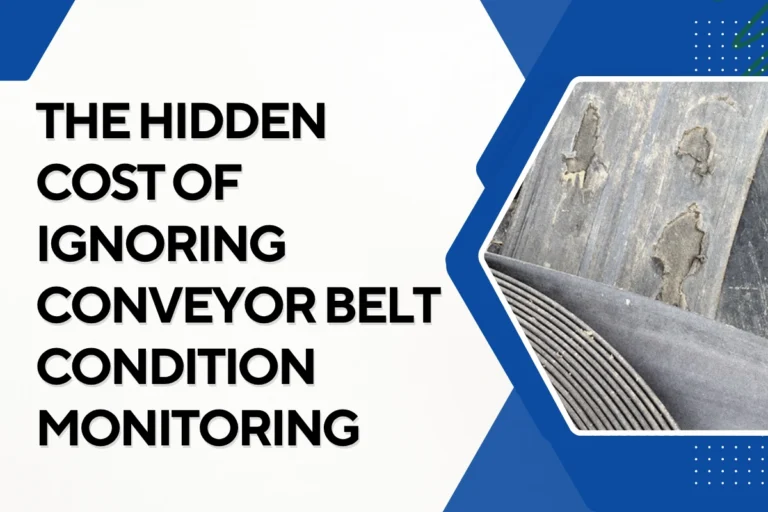

Machine Condition Monitoring

Maintenance Management

Root Cause Analysis

Asset Health and Performance Dashboards

Integration with Other Systems

Data-Driven Analytics and Reporting

Lifecycle Management

Why Asset Performance Management Important in Smart Manufacturing

Data Driven Decision Making

Improved Operational Efficiency

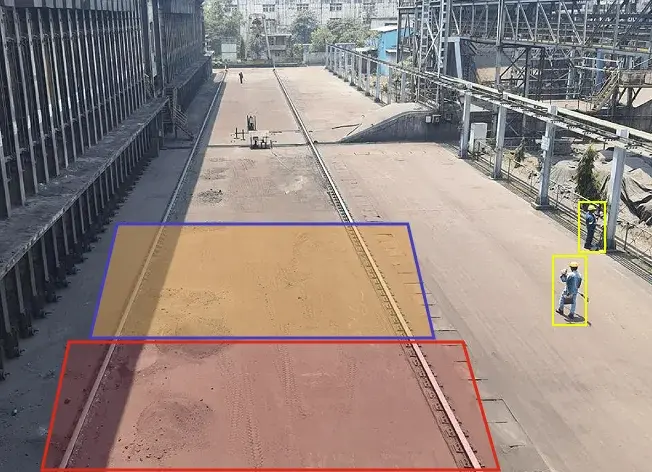

Improved Safety and Compliance

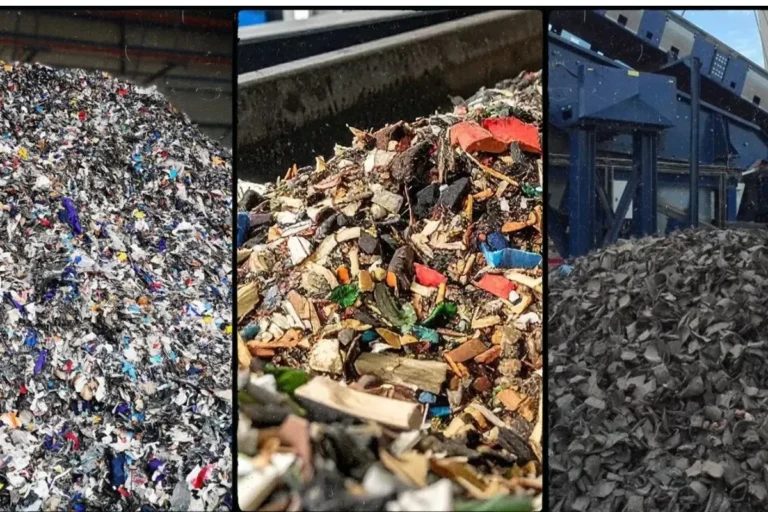

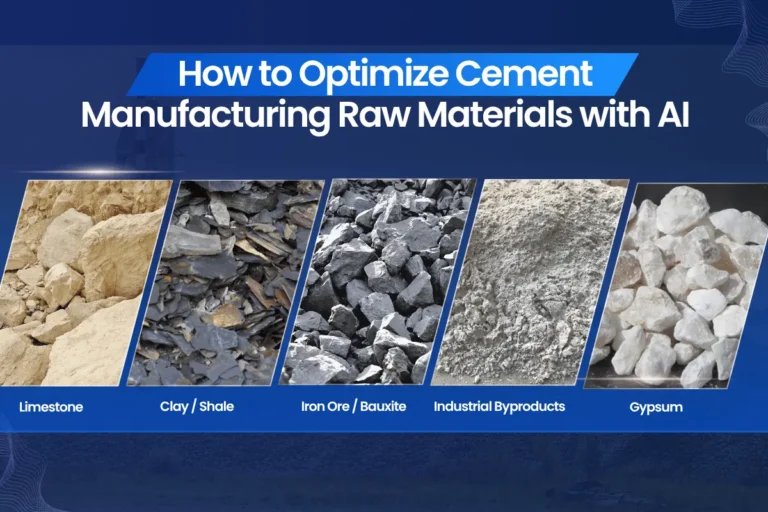

Computer Vision AI in Asset Performance Management

Benefits of Asset Performance Management software

Real-Time Monitoring

Increased Uptime and Reliability

Predictive Maintenance

Better Decision Making

Collaboration and Communication

Safety and Compliance

Conclusion