Big Rock Detection

Prevent crusher breakdown in cement plant Introducing JamGuard- Prevent Crusher Jams and Eliminate Downtime...

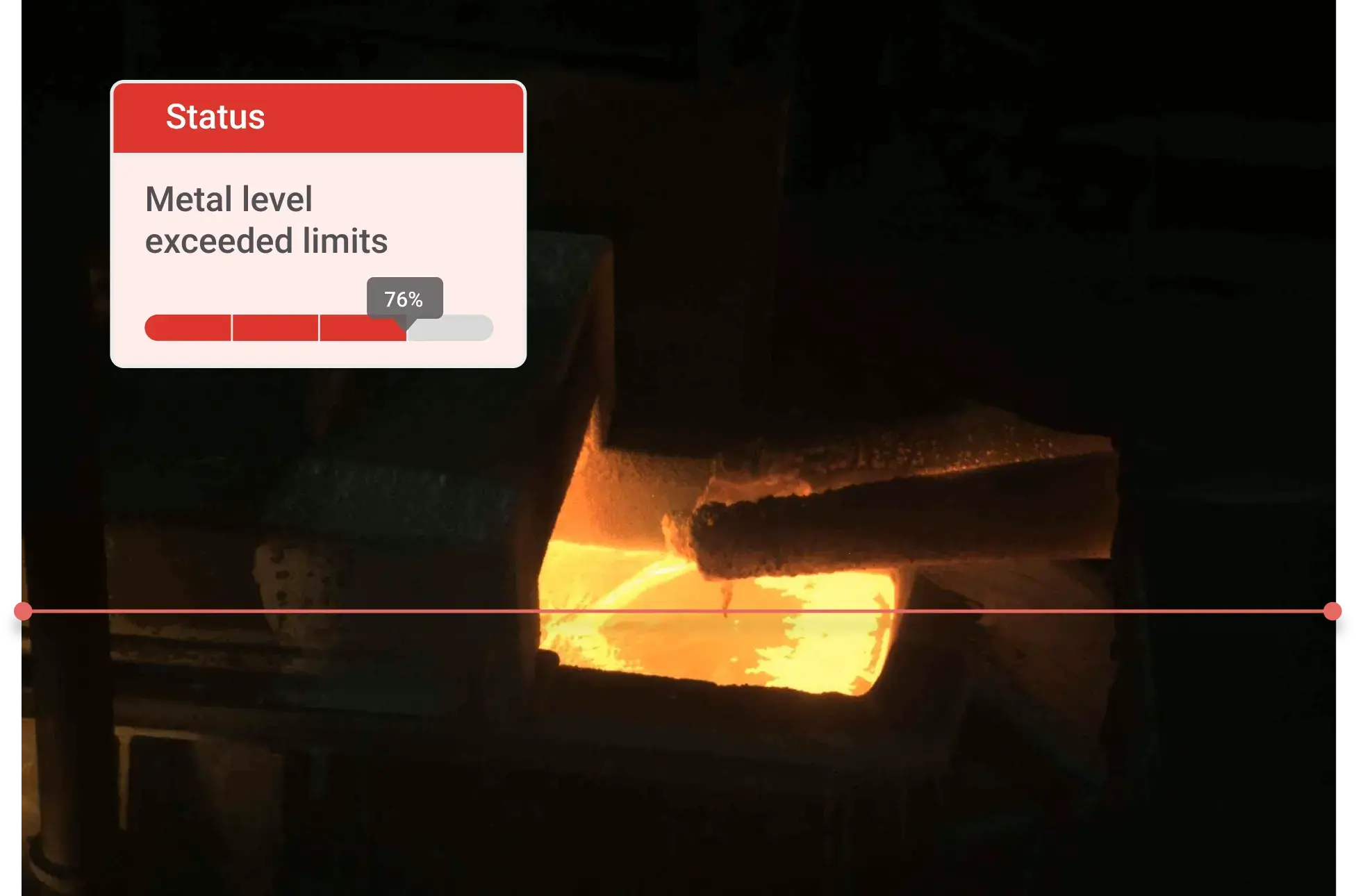

Ladle Management

Vision AI agents tracks ladle movements, reducing the risk of spills, accidents, and misalignment, causing...

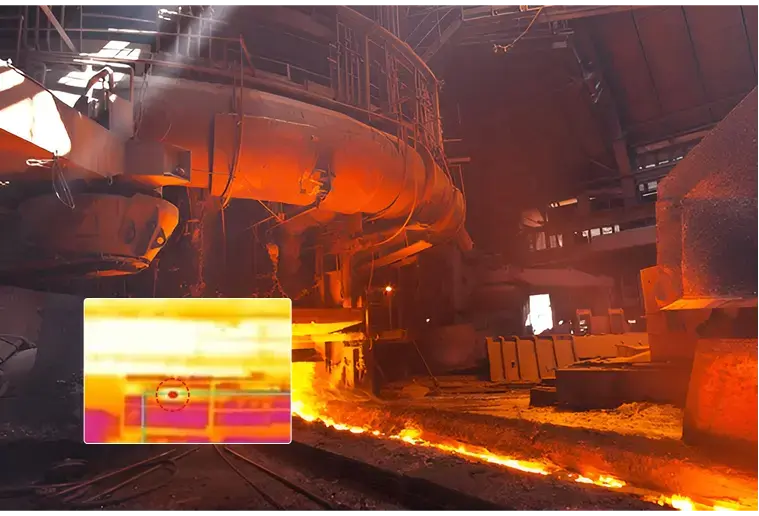

Blast Furnace Operations

Enhance blast furnace stability, efficiency, and productivity with AI agents driven insights.

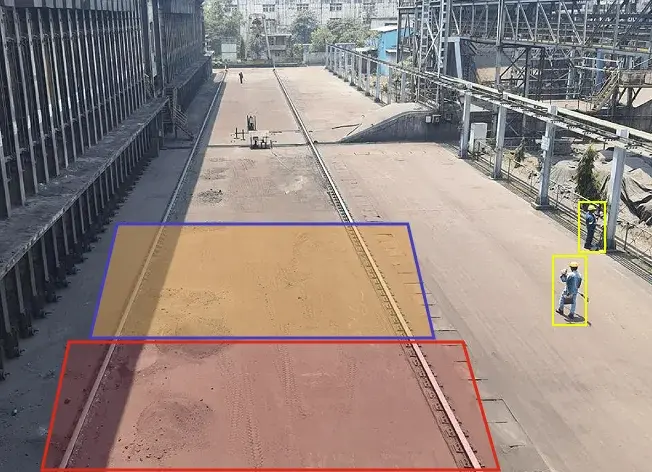

Stockpile Management

Gain real-time, accurate measurements to improve stockpile inventory management, reduce waste, and enhance...

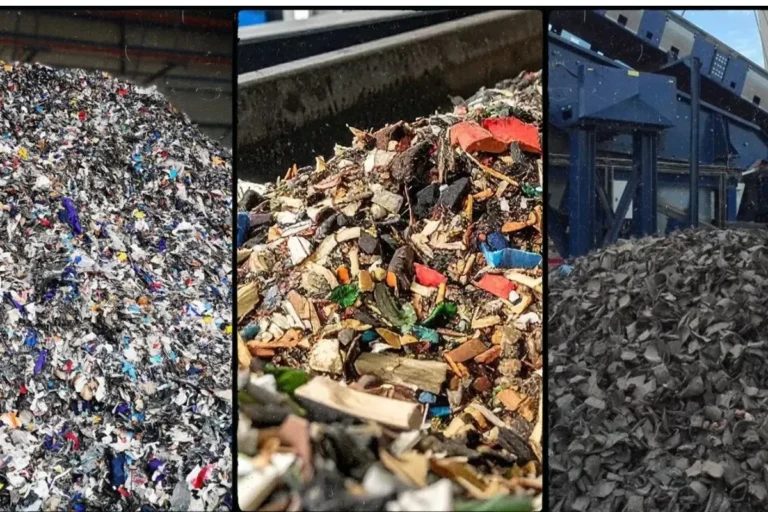

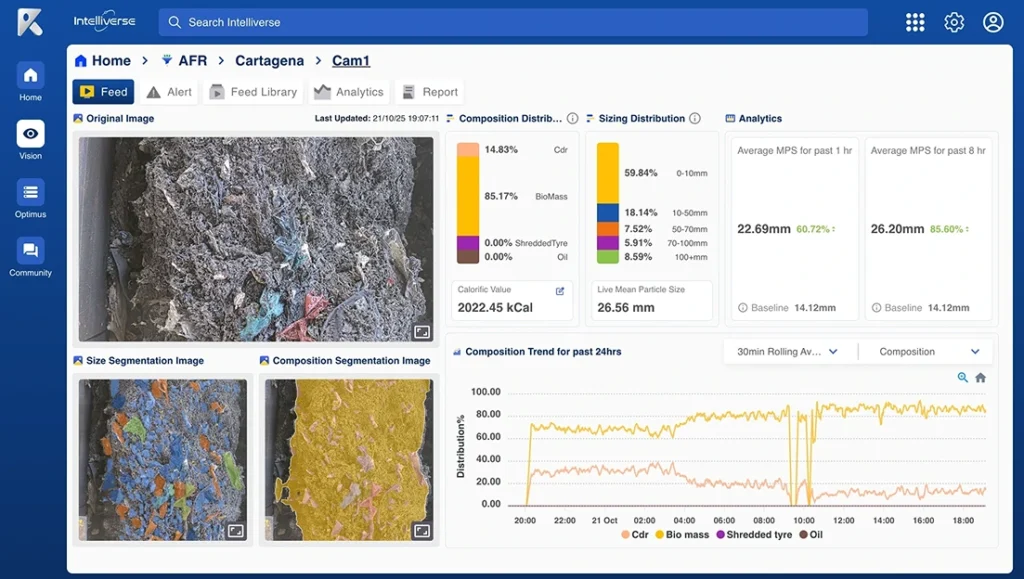

Alternative Fuels

AI for Calorific Value Estimation Optimize Alternative Fuels in cement industry with MatScan – our AI...

Moisture Detection

Enhance energy efficiency with real-time AI agents to manage material moisture analysis with IR Came...

Kiln Refractory Monitoring

Reduce unexpected downtime, gradual wear, and degradation of refractory linings in cement kilns

Cement kiln

Elevate cement kiln operations and achieve optimal process control every time with our AI agents.

Conveyor Belt Monitoring

AI agents manage conveyor systems by providing real-time insights, detecting wear, misalignment, and...