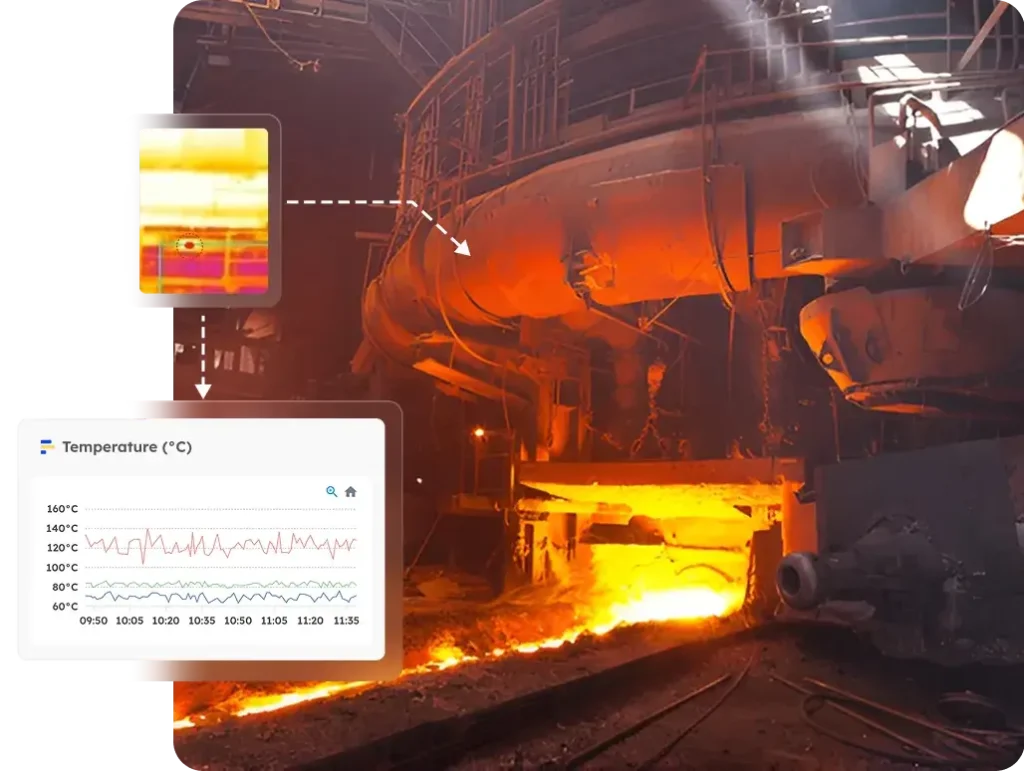

70% Reduction in downtime of conveyor failures with conveyor monitoring

Achieved 70% Reduction in downtime of conveyor failures with Ripik AI conveyor belt monitoring system. This ensured smoother operations, minimized downtime, and delivered significant cost savings.