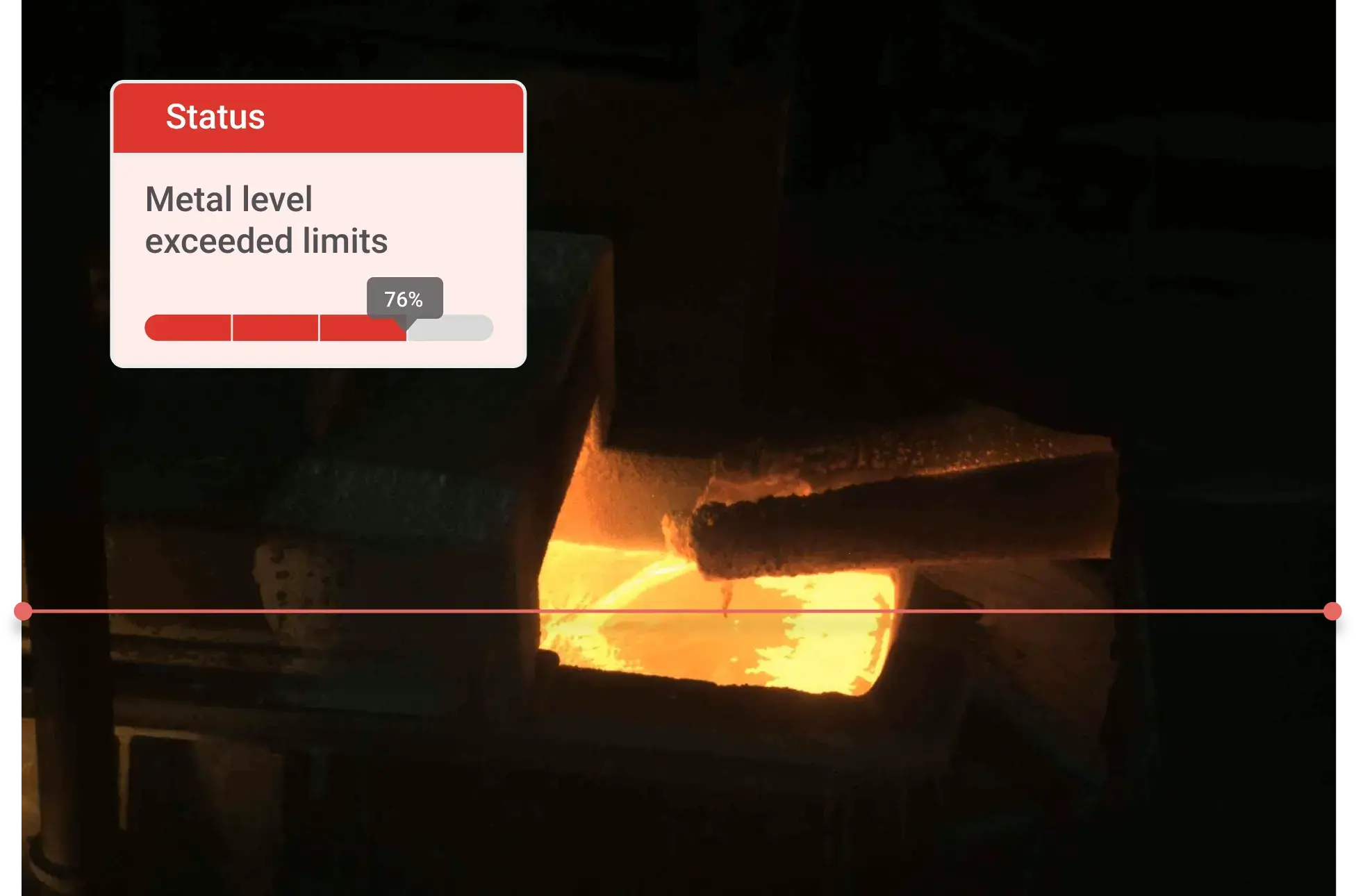

Frequent Overflows and Metal Spillage

Inconsistent Steel Composition and Quality

Inefficient Vacuum Degassing Operations

High Energy Consumption and Poor Furnace Efficiency

Slag Carryover and Product Contamination

Reduced Metal Yield and Higher Material Loss

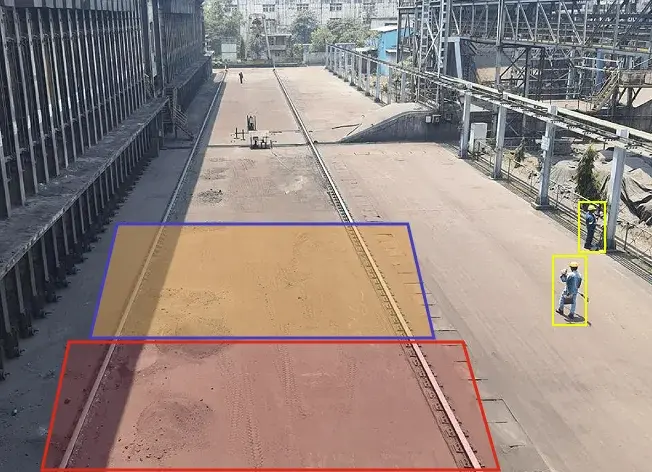

Increased Safety Risks for Operators

Frequent Maintenance and Equipment Downtime

Environmental and Resource Inefficiency

The Harsh Realities of Measuring Molten Metal

Key Environmental Challenges

- Extreme Temperature: Traditional sensors and probes cannot withstand the intense heat or radiation from molten metal baths, where temperatures often exceed 1,600°C, causing rapid degradation and signal distortion.

- High Dust and Smoke: Dense fumes, dust, and combustion gases scatter infrared and laser beams, making it difficult for optical systems to maintain reliable readings and reducing overall signal accuracy.

- Electromagnetic Noise: Heavy electrical currents generated by induction furnaces and electric arc furnaces (EAFs) interfere with electronic sensors, resulting in data noise, unstable readings, or complete signal loss.

- Continuous Turbulence: Constant bubbling, gas stirring, and surface waves create fluctuations that misrepresent the actual molten metal level, leading to inaccurate and inconsistent measurements.

- Slag Interference: The floating slag layer on top of molten metal often reflects or absorbs sensor signals, making it difficult for traditional systems to differentiate between slag and metal surfaces.

Why Traditional Measurement Systems Fail?

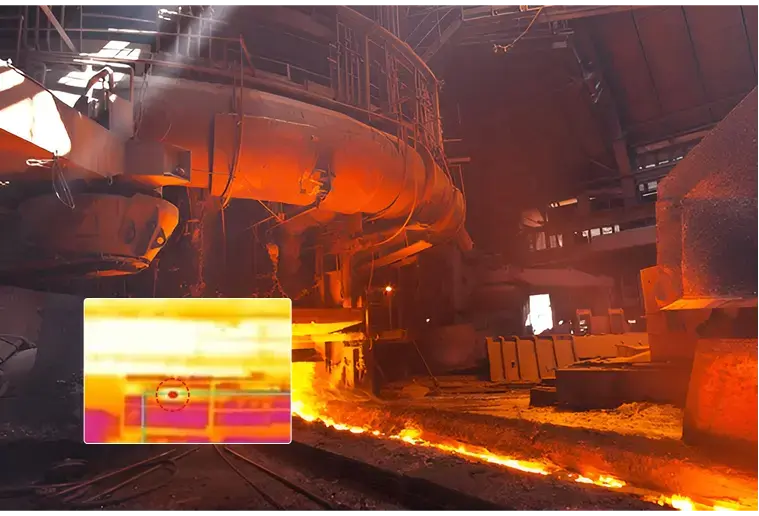

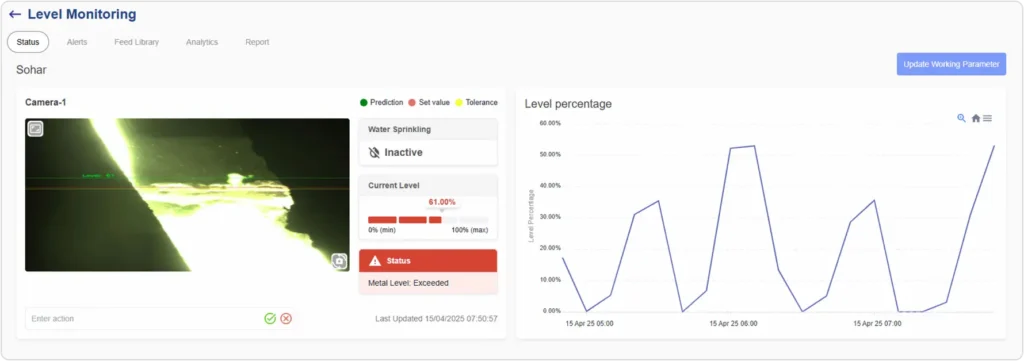

How Vision AI-Based Level Monitoring Enables Molten Metal Level Control?

Key Features and Functional Capabilities

High-end hardware

Real-Time Level Monitoring

Programmable Closed-Loop Control

Real-Time Alerts and Notifications

Analytics and Reporting Dashboard

Feed Library and Historical Playback

Different Types of Molten Metal Level Monitoring Systems in Steel Plants

Blast Furnace Level Monitoring System

Torpedo Car Level Monitoring System

Basic Oxygen Furnace (BOF) Level Monitoring System

Ladle Molten Metal Level Monitoring System

Vacuum Degasser Level Monitoring System

Tundish Level Monitoring System

Mold Level Monitoring System (Continuous Casting)

Benefits of Molten Metal Level Control Systems in Steel Plants

- Improved Process Stability and Accuracy: Fluctuations in molten metal levels can disturb temperature balance and affect refining or casting performance. Automated molten steel level monitoring ensures consistent bath height, allowing smooth control of tapping, pouring, and refining operations. This stability minimizes human error, enhances reaction uniformity, and ensures steady, predictable results across production cycles.

- Enhanced Product Quality: Accurate molten metal level measurement directly influences the chemical consistency and surface finish of steel. When levels are precisely controlled, it prevents defects like inclusions, blowholes, or surface cracks. Stable level monitoring also helps maintain cleaner separation between slag and metal, leading to improved purity and overall product quality.

- Prevention of Overflows and Material Loss: Uncontrolled metal levels can cause overfilling, spills, or under-tapping — all of which waste valuable molten steel and damage equipment. The AI-based level monitoring system detects level changes in real time and automatically triggers control actions to prevent such losses. This precision improves yield, reduces waste, and keeps operations safer and more efficient.

- Reduced Downtime and Maintenance: Unexpected overflows, slag buildup, and tapping delays are major contributors to downtime in steel plants. Automated level monitoring prevents such issues by keeping molten metal levels within safe operating limits. This reduces wear on refractories, minimizes maintenance interventions, and increases the lifespan of furnaces and ladles — resulting in more uptime and smoother production flow.

- Lower Energy and Fuel Consumption: Stable molten levels help maintain uniform heat transfer and prevent energy loss. Consistent molten metal level control means furnaces no longer need to overheat to compensate for uneven levels. As a result, plants experience lower fuel consumption in the steel production process, improved energy efficiency, and reduced operational costs.

- Improved Operator Safety: Traditional manual monitoring exposes operators to high heat, glare, and splash hazards. By replacing visual inspections with automated molten metal level detection, AI systems keep personnel away from danger zones. Remote visualization and automatic alerts create a safer work environment without compromising accuracy.

- Real-Time Insights and Predictive Capabilities: The latest AI-based level monitoring systems provide real-time visibility into molten steel and slag behavior. They integrate with slag detection systems and Vacuum Degassing Level Monitoring platforms to deliver predictive insights that help operators identify process deviations early. This data-driven approach supports smarter decision-making and continuous process improvement.

- Better Integration with Automation Systems: These systems easily connect with plant PLCs, DCS, and MES setups, creating a unified automation framework. The integration allows closed-loop control of furnaces, ladles, and degassing units, supporting the move toward Industry 4.0 and fully digital steel plants. Consistent molten metal level control ensures all processes stay synchronized, improving coordination between melting, refining, and casting.

- Higher Yield and Overall Efficiency: With accurate measurement, reduced downtime, and improved process synchronization, steel plants achieve higher throughput and better material utilization. The molten metal level control system ensures every drop of molten steel is used efficiently, maximizing yield while maintaining quality and sustainability targets.