How AI Is Transforming Sustainability in Manufacturing

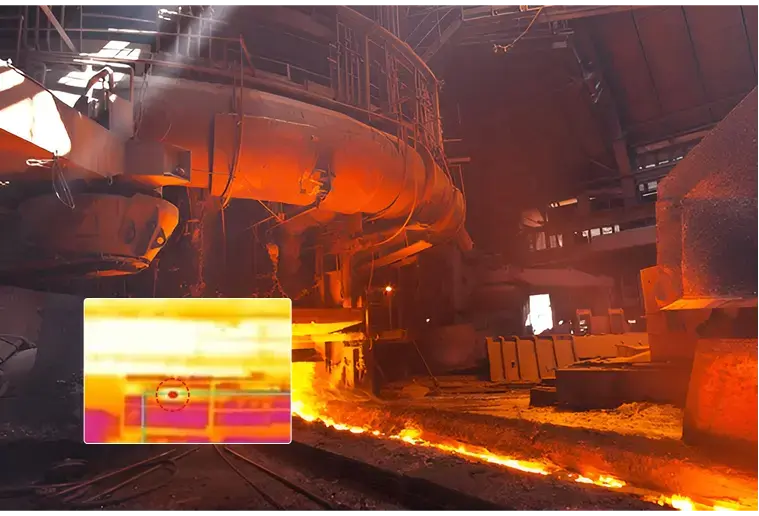

Carbon footprint reduction

Benefits of carbon emissions monitoring

- Regulatory compliance: Meet local and global environmental criteria to stay out from under fines.

- Improved business value: Efforts at emission reduction will help businesses stand out to environmentally-minded consumers.

- Energy savings: The right use of energy results in reduced costs, which helps the environment and the company’s budget.

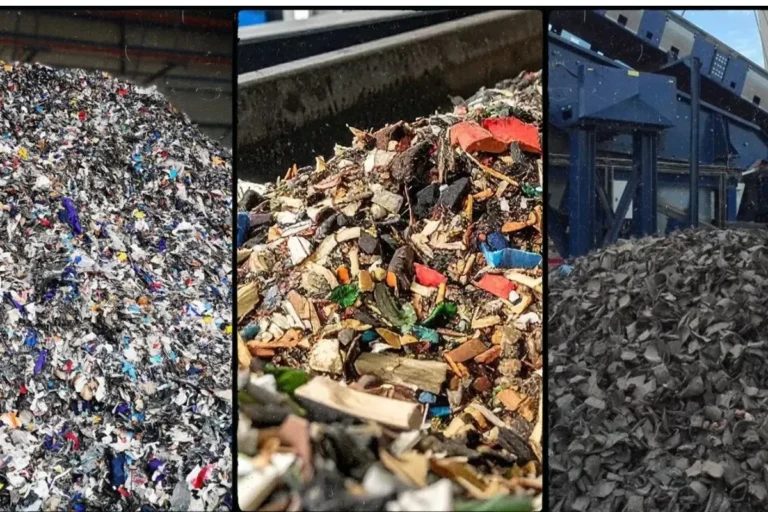

Treatment of effluents and hazardous chemicals

Benefits of proper handling of ETP

Improved effluent discharge: Controlled set parameters ensure permissible chemical discharge and lesser harm to the environment.

Reduced waste: A circular economy is supported by only discharging chemicals as necessary, therefore lowering waste.

Compliance: Controlled ETP and hazardous chemical discharge ensures the organization stays within the compliance and pollution control regulations.

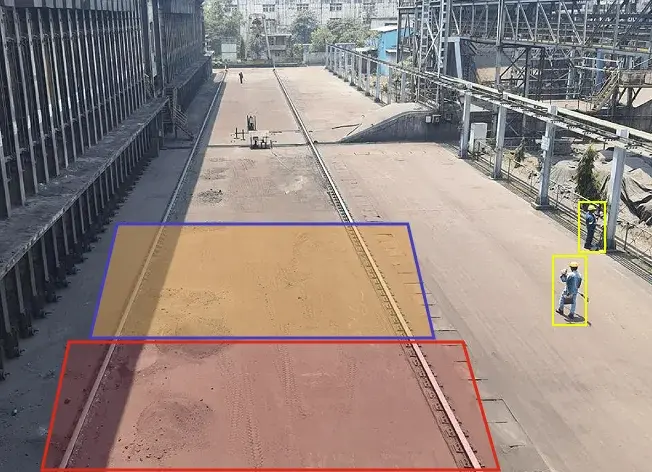

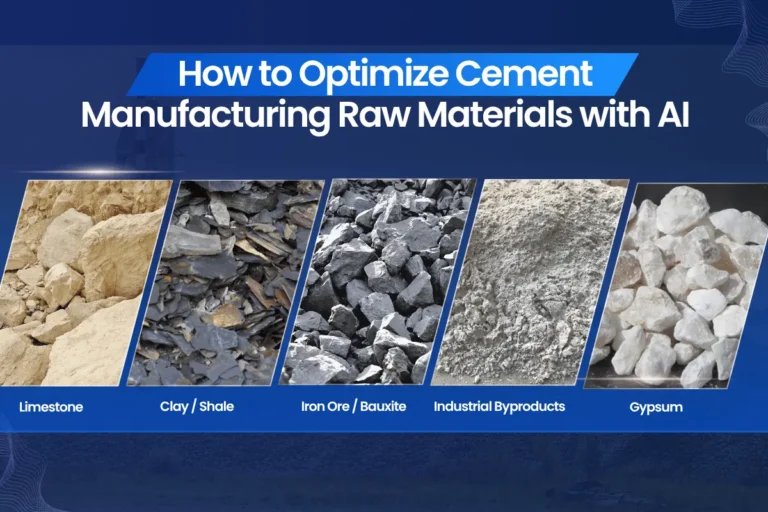

Optimizing resource utilization

Benefits of resource optimization

Waste reduction: Real-time tracking helps decrease waste by guaranteeing the exact usage of resources where and when they are needed.

Reduced costs: Effective resource utilization maximizes return on investment by means of significant cost savings.

Environmental impact: By using optimum raw materials, the production processes ensure a reduced carbon footprint, aligning with AI for environmental sustainability goals.

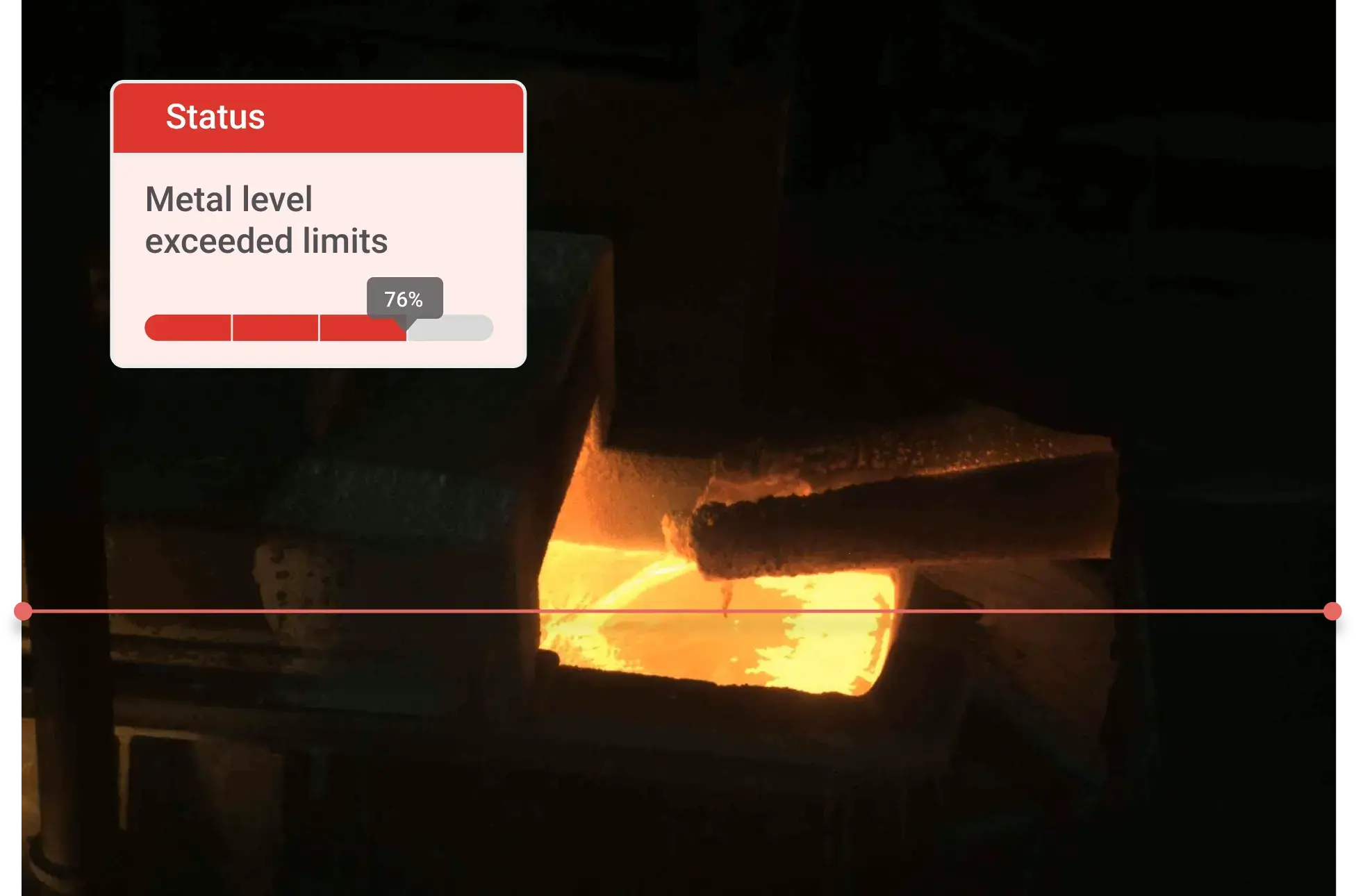

Quality control with computer vision AI

Benefits of quality control

Improved precision: Real-time tracking helps decrease waste by guaranteeing the exact usage of resources where and when they are needed.

Reduced rework: With fewer defective products, there’s less need to reprocess items, which conserves resources.

Increased customer satisfaction: Superior quality control leads to better customer satisfaction and brand loyalty.

Final Thoughts: Building a Sustainable Future with AI