Reactive or Ineffective Maintenance Strategies

Lack of Real-Time Visibility and Condition Monitoring

Human Error and SOP Non-Compliance

Skipping daily inspection routines

Misinterpreting sensor readings

Failing to follow standard operating procedures

Not logging anomalies or minor faults

Lack of Equipment Redundancy and Failover Mechanisms

Ineffective Maintenance Planning and Communication

How AI Addresses Uptime Challenges

Predictive maintenance strategies

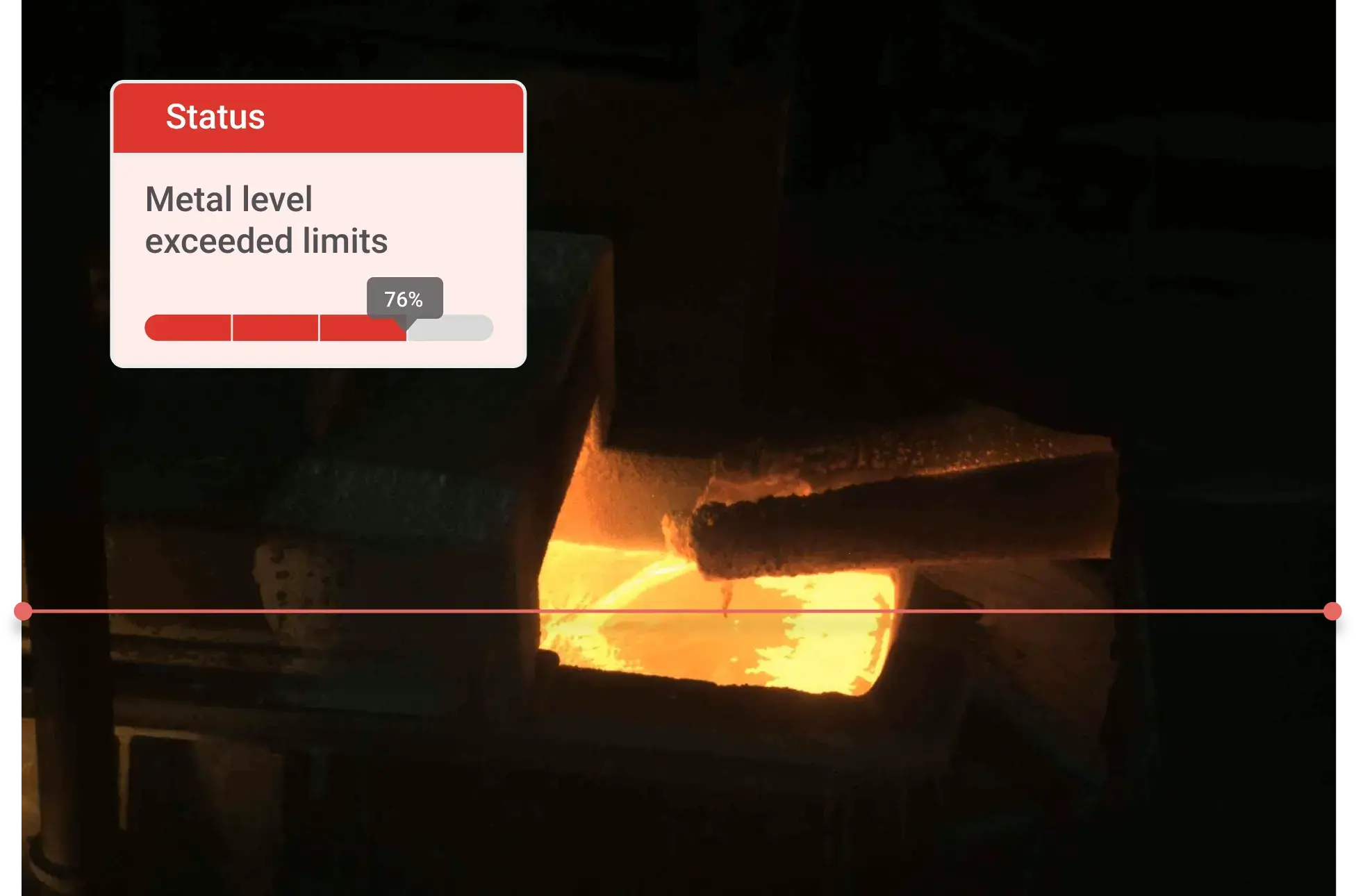

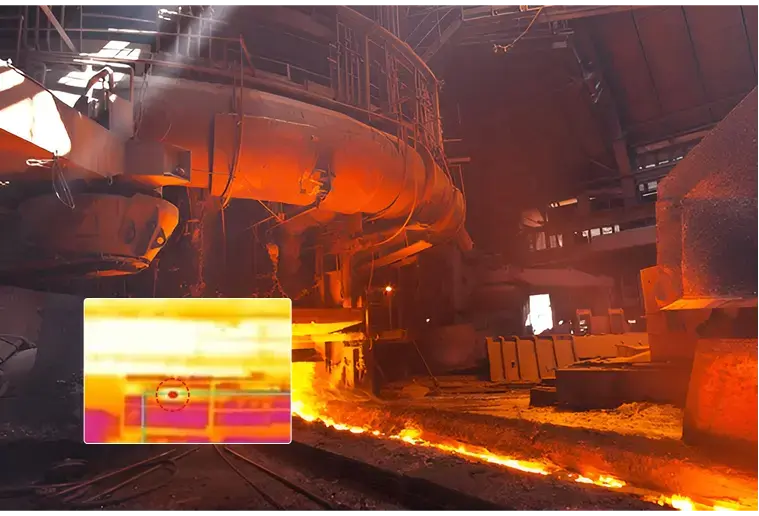

Real-Time Anomaly Detection

Real-Time Quality Monitoring

Optimizing Energy and Sustainability

AI Architecture for Uptime Optimization

Data Collection Layer

Edge + Cloud Hybrid Infrastructure

AI Model Training and Deployment

MES and Maintenance System Integration

Applications of AI to Improve Manufacturing Uptime

Refractory Monitoring

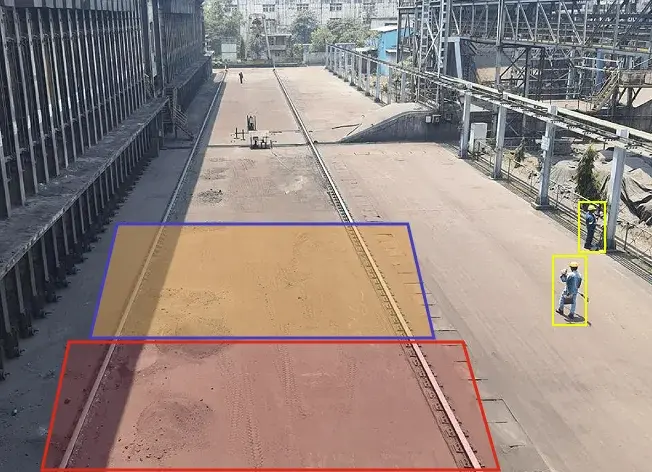

Workforce Handling and Safety

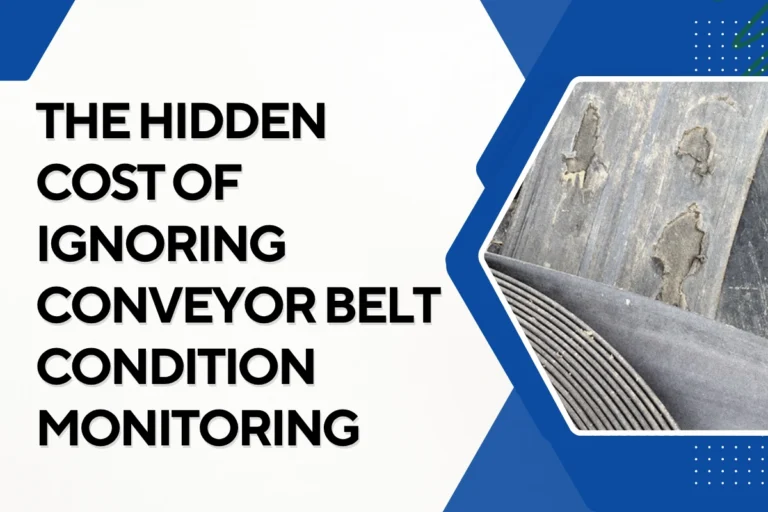

Conveyor Anomaly Detection

Real-World Use Cases and Results

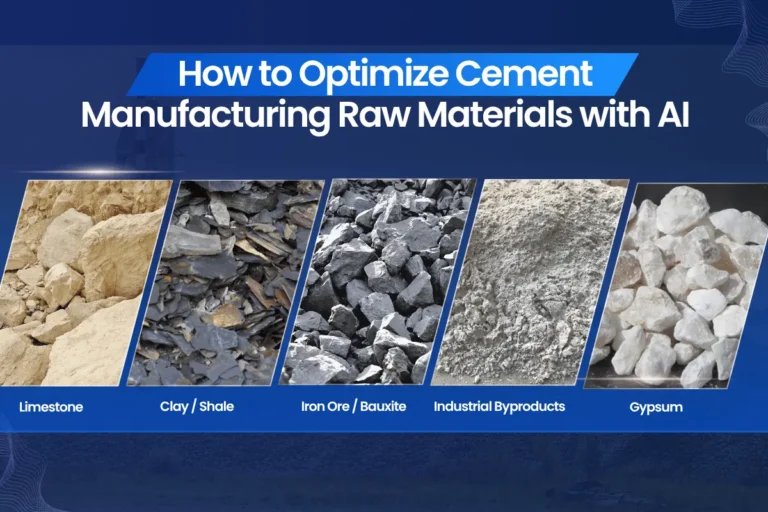

Problem

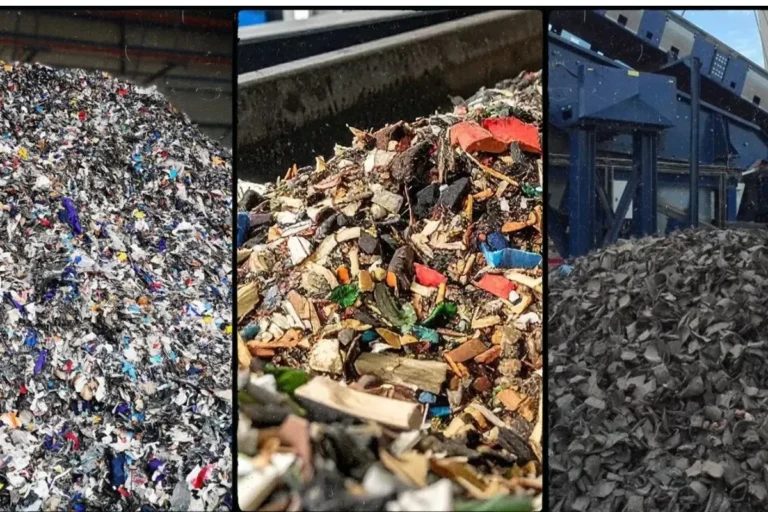

Oversized rocks disrupt crushers, leading to blockages in crushers, increased downtime and reduced operational efficiency.

Solutions

Big Rock Detection for Grinding Unit for Minimizing Downtime

Impact

80% reduction in equipment damage with big rock detection in cement plant