Impact of Adopting Alternative Fuels

Low melting point

Complexity

Operational inefficiencies and quality

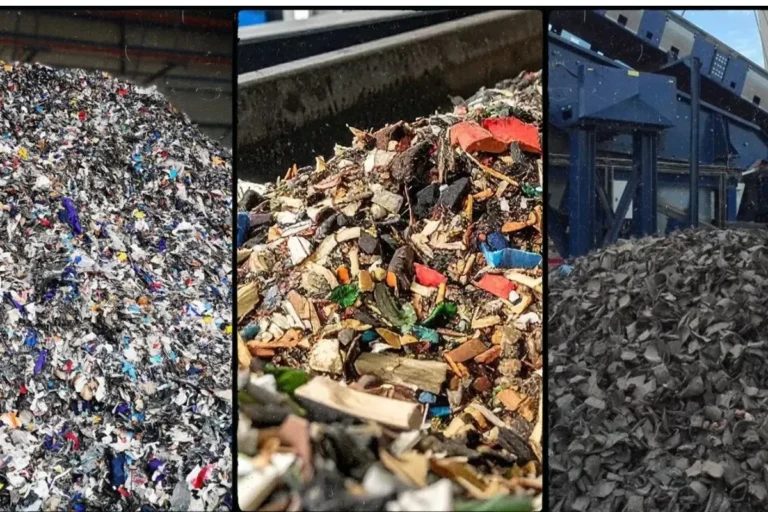

RDF Quality Requirement for Cement Kiln

Leveraging AI for Alternate Fuel Analysis

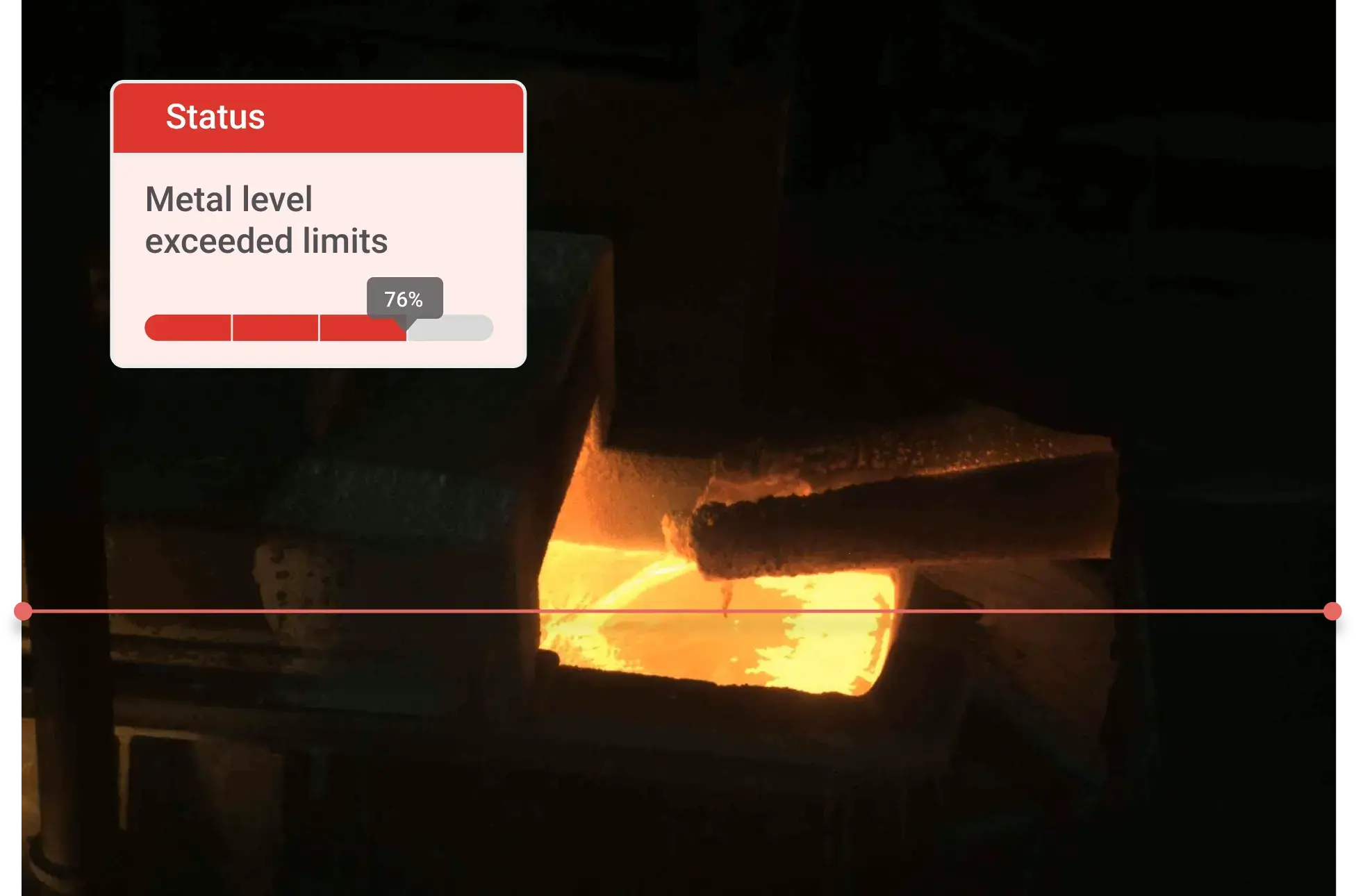

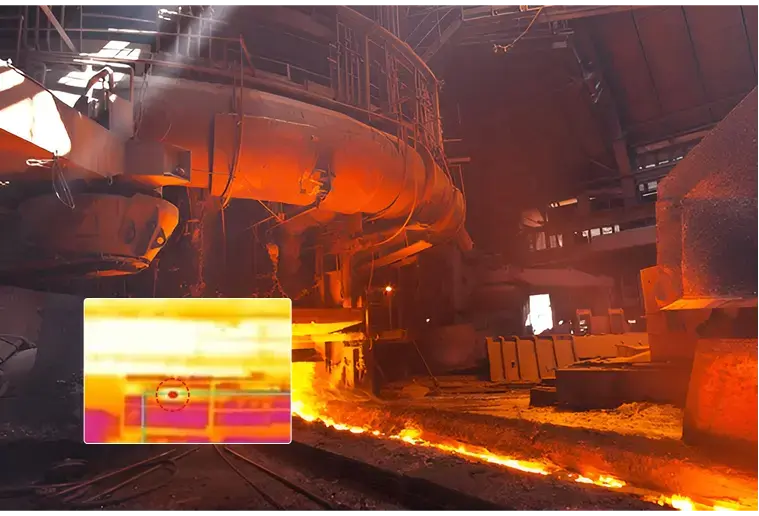

Anomaly detection to enhance process control

Features supporting process control for anomaly detection

Data engineering and visual data lake creation: This is the first step in achieving advanced process control using visual AI. Real-time monitored data from the plant or cement kiln is stored and analyzed for immediate control or later evaluation to identify potential deviations. A data lake enables the integration, processing, and analysis of video data from multiple sources. It also supports data visualization and creates automated workflows for operational efficiency.

Self-cleaning mechanism: Cement manufacturing operates in a dusty environment where camera lenses can quickly become dirty, obscuring visuals. The self-cleaning mechanism uses sensor detection to identify contaminants on the lens and clean it automatically, ensuring uninterrupted monitoring.

Application-based and WhatsApp alert system: Alerting users to detected anomalies is as important as the detection itself. Modern AI vision systems connected through mobile and desktop applications can send alert notifications instantly. Additionally, WhatsApp notifications allow supervisors to receive alerts even when they are away from the plant.

Determining material proportion to estimate calorific value

Monitoring key parameters

Moisture detection

Detection of large particles

Enhancing the control system

Volumetric analysis

In a Nutshell