What Is Particle Size Analysis?

Understanding Particle Size Analysis in Heavy Industry

Challenges due to lack of Automated Particle Size Analysis

Inconsistent Product Quality

Suboptimal Raw Material Utilization

Reduced Process Efficiency

Increased Energy Consumption

Increased Equipment Wear and Downtime

Costly Material Wastage

Environmental Impact

Traditional vs. Modern Methods of Particle Size Distribution

Traditional Methods and Their Limitations

Sieve Analysis – This method involves passing a sample through stacked sieves with different mesh sizes. While widely used, it is labor-intensive, time-consuming, and prone to inconsistencies due to variations in handling and shaking intensity.

Laser Diffraction – Uses a laser beam to illuminate dispersed samples, with the resulting light scattering providing critical data for determining particle size distributions. However, it requires frequent calibration, is sensitive to sample conditions, and does not provide real-time monitoring. Parameters such as diffusion coefficient and refractive index are often used in laser diffraction and DLS for accurate measurement.

Manual Microscopy – Involves visually inspecting particles under a microscope and measuring their size manually or with software. This method is slow, prone to human error, and impractical for large-scale operations. Advanced techniques such as electron microscopy and scanning electron microscopy offer high-resolution particle analysis, enabling detailed visualization of nanoparticle size, morphology, and surface features.

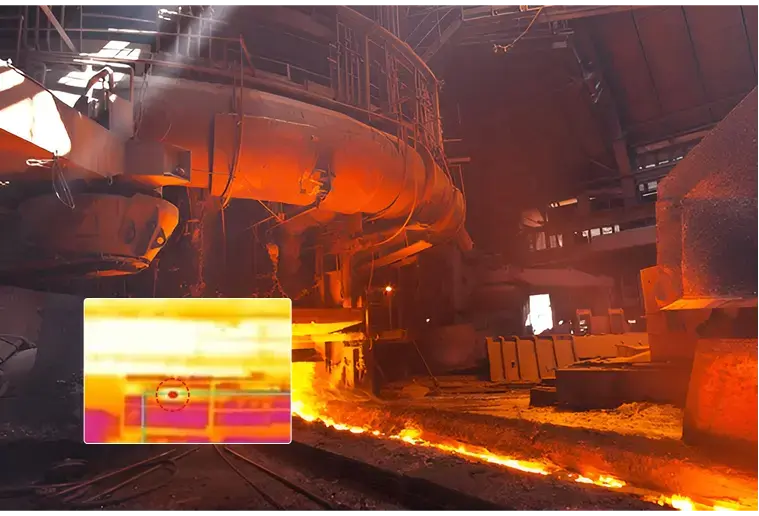

Modern Methods: AI-Powered Dynamic Image Analysis

How Vision AI Enable Automated Particle Size Analysis

Key Features of Particle Size Measurement

Real-Time Particle Size Monitoring

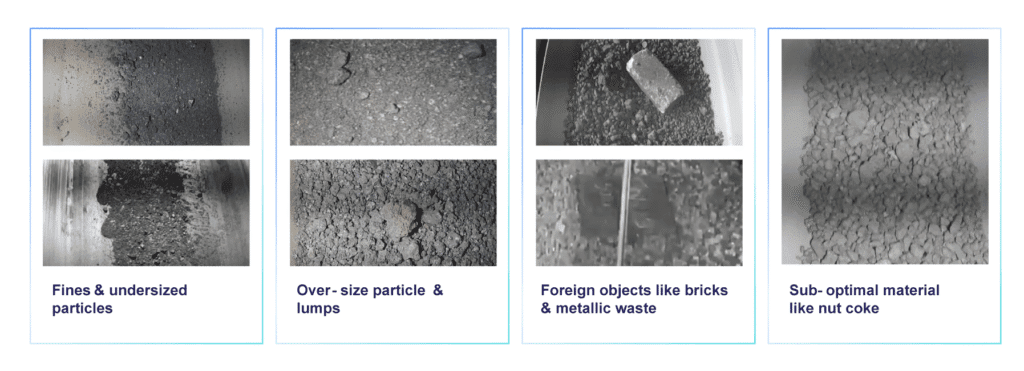

Automated Anomaly Detection

Granulometry Analysis & Particle Size Distribution

Instant Alerts

Analytics Insights

Historical Video Feeds & Reporting

Real-World Applications of Particle Size Analysis

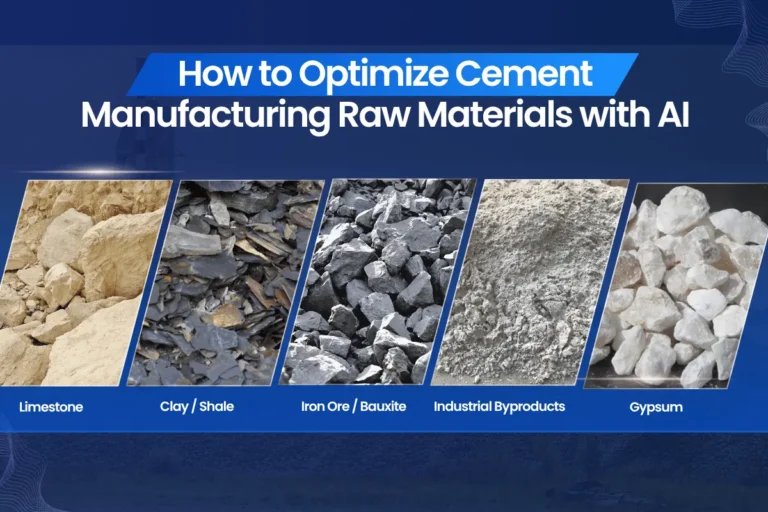

Cement Industry

Problem:

Inconsistent Kiln Efficiency: Without proper granulometry analysis, raw materials may not burn uniformly, leading to inconsistent combustion in the kiln. This results in inefficient fuel consumption and suboptimal temperatures.

Clinker Quality Variability: Poorly sized particles in raw materials can lead to clinker inconsistencies, affecting the final cement product’s strength and durability.

Increased Wear and Tear on Equipment: Inconsistent particle sizes cause abrasion and clogging in mills and conveyors, increasing maintenance costs and reducing equipment lifespan.

Solution:

Automated Particle Size Analysis: Implementing real-time, automated particle size analysis ensures that the raw materials, including coal and limestone, are consistently sized for optimal combustion. This reduces fuel consumption, stabilizes temperature, and enhances clinker quality. Quality control in this process is crucial for maintaining product consistency and compliance with regulatory standards.

Optimization of Grinding Process: Real-time monitoring of coal particle size distribution and limestone particle size allows for better control over the grinding and blending process. This results in a more uniform product and improved cement quality.

Equipment Maintenance Planning: Automated Particle Size Monitoring systems provide data that can predict when maintenance is required, minimizing unplanned downtime and extending the lifespan of machinery.

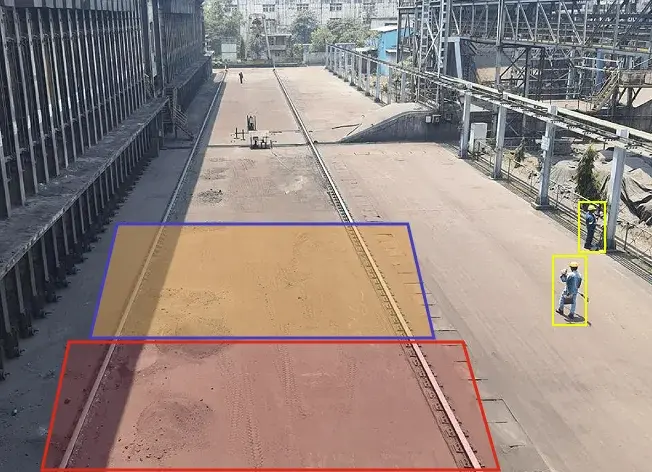

Steel Industry

Problem:

Inconsistent Steel Quality: Variations in raw material size can lead to defects in sintering, pelletizing, and blast furnace operations, resulting in poor-quality steel.

Inefficient Blast Furnace Operation: Without proper granulometry analysis, the blast furnace may experience an improper burden mix, leading to suboptimal fuel consumption and reduced productivity.

Increased Energy Use: Improperly sized raw materials force equipment to work harder, increasing energy consumption and operational inefficiency.

Solution:

- Precise Material Sizing: Implementing automated particle size analysis ensures that iron ore and other materials are within the ideal range for sintering, pelletizing, and Computer blast furnace operations. This enhances steel quality and reduces energy consumption by optimizing processing.

- Burden Mix Optimization: Real-time particle size data enables better control over the burden mix in blast furnaces, improving fuel efficiency and increasing overall productivity.

- Energy Optimization: With AI sizing, energy usage during the processing of raw materials is optimized, leading to lower energy costs and more sustainable operations.

Chemical Industry

Problem:

Inefficient Reactions and Lower Yield: The presence of small particles significantly affects the surface area and reactivity of materials in chemical processes. Without accurate material sizing, catalytic reactions may be inefficient, reducing product yield.

Inconsistent Product Quality: Precise particle sizing is crucial for uniformity in chemical products, such as fertilizers or coatings. Inconsistent particle sizes can lead to variations in texture, solubility, or effectiveness.

Increased Equipment Wear: Suboptimal particle sizes can cause more friction and wear in equipment like mixers and grinders, increasing maintenance costs.

Solution:

Real-Time Particle Size Monitoring: Automated granulometry analysis continuously monitors particle size, allowing for immediate adjustments to optimize reaction rates and improve yield.

Consistency in Product Quality: By controlling particle size precisely, manufacturers can ensure consistent quality across batches, reducing waste and improving customer satisfaction.

Reducing Equipment Wear: Automated granulometry analysis ensures proper particle sizing, which reduces friction and wear on machinery, lowering maintenance and replacement costs.

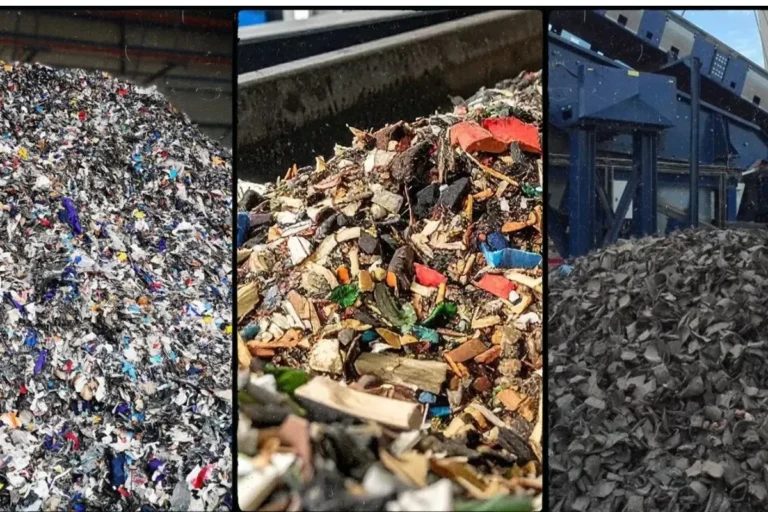

Mining Industry

Problem:

Inefficient Ore Processing: Without particle size analysis, ores may be improperly ground, reducing the efficiency of extraction processes and leading to lower yields.

Increased Energy Costs: Improperly sized particles can lead to over-grinding or under-grinding, increasing energy consumption and lowering profitability.

Environmental Impact: Inefficient particle size control can lead to problems in tailings disposal and water recovery systems, affecting environmental sustainability.

Solution:

Optimized Grinding and Processing: Automated particle size distribution analysis ensures that ores are processed at the ideal size, maximizing extraction efficiency and reducing waste.

Energy Efficiency: Automated systems ensure that energy consumption is minimized by adjusting grinding processes to prevent over-grinding and under-grinding.

Environmental Management: Proper particle sizing helps to manage tailings disposal more efficiently, reducing environmental impact and ensuring compliance with regulations.

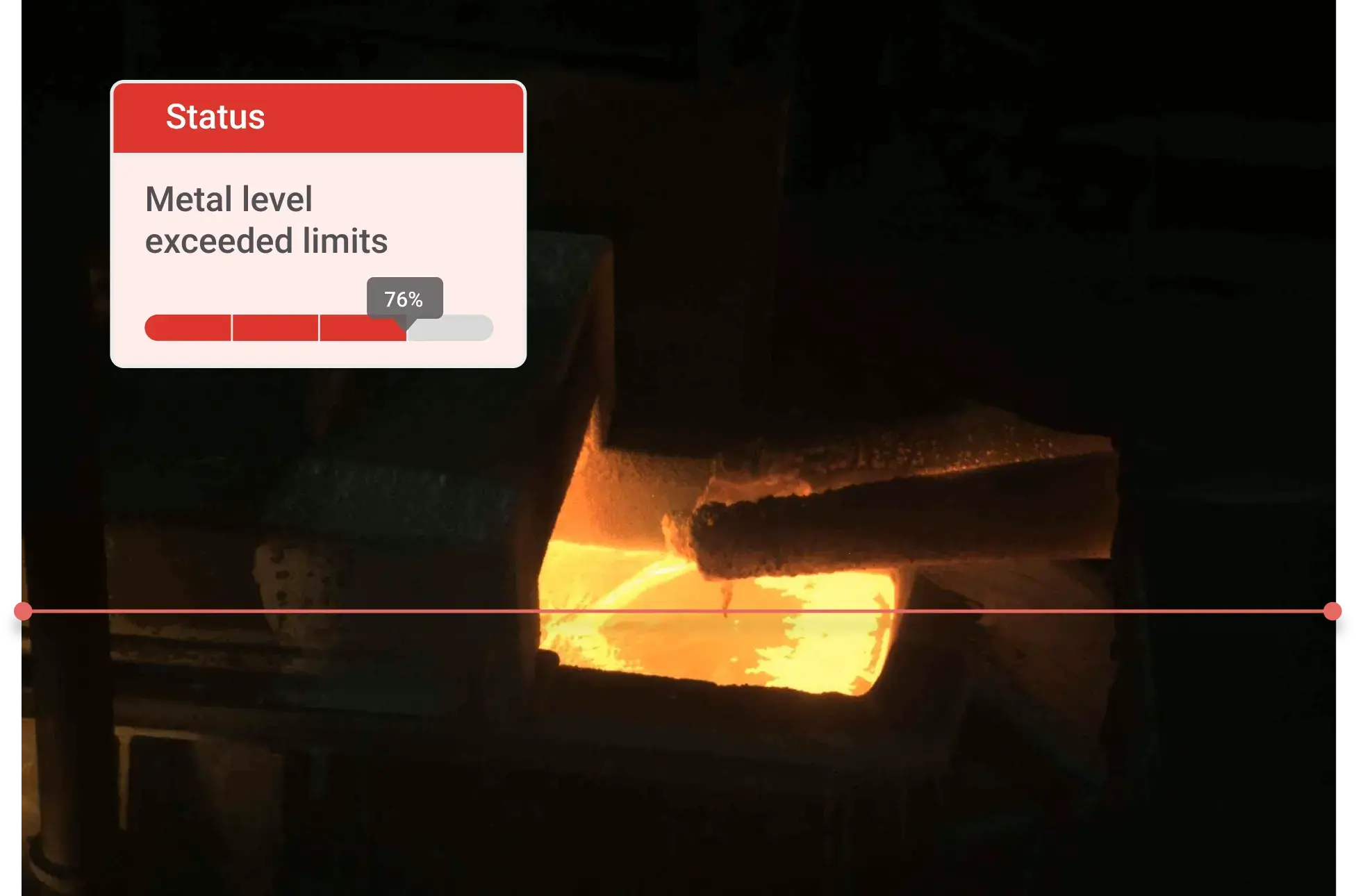

Power Plants (Coal and CFBC Boilers)

Problem:

Inconsistent Combustion: Without proper coal particle size distribution analysis, coal combustion may be inefficient, leading to higher fuel consumption, lower efficiency, and increased emissions.

Poor Boiler Efficiency: In CFBC boilers, improper coal sizing can reduce combustion efficiency, affecting heat transfer and increasing operational costs.

Equipment Damage: Incorrect particle sizes can cause blockages and wear on feed systems and burners, resulting in costly repairs and downtime.

Solution:

Optimized Fuel Sizing: Automated coal particle size analysis ensures that coal is properly sized for optimal combustion, improving efficiency and reducing emissions.

Enhanced Boiler Efficiency: By maintaining consistent coal particle sizes, CFBC boilers operate more efficiently, optimizing heat transfer and reducing operational costs.

Reduced Equipment Wear: Real-time monitoring of coal particle size helps prevent equipment damage by ensuring that coal is properly sized, reducing blockages and wear on machinery.

Conclusion