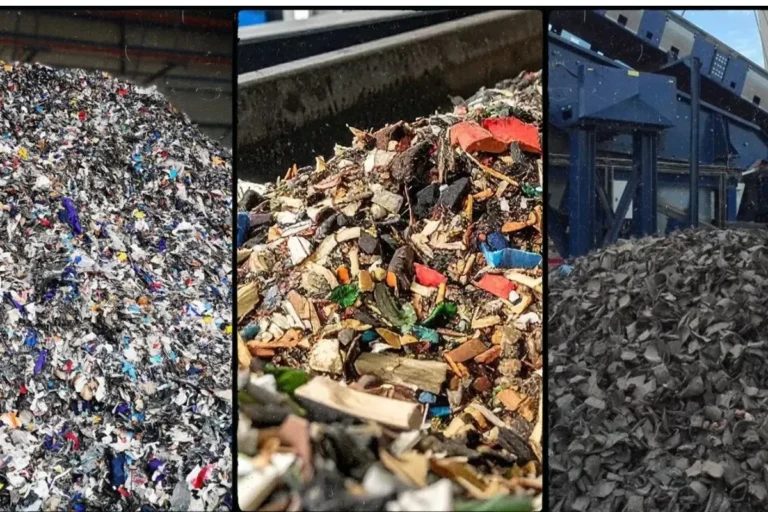

Foreign Particles and Sharp Objects

Lack of Real-Time Monitoring Systems

Inaccurate Stockpile Volume Estimation

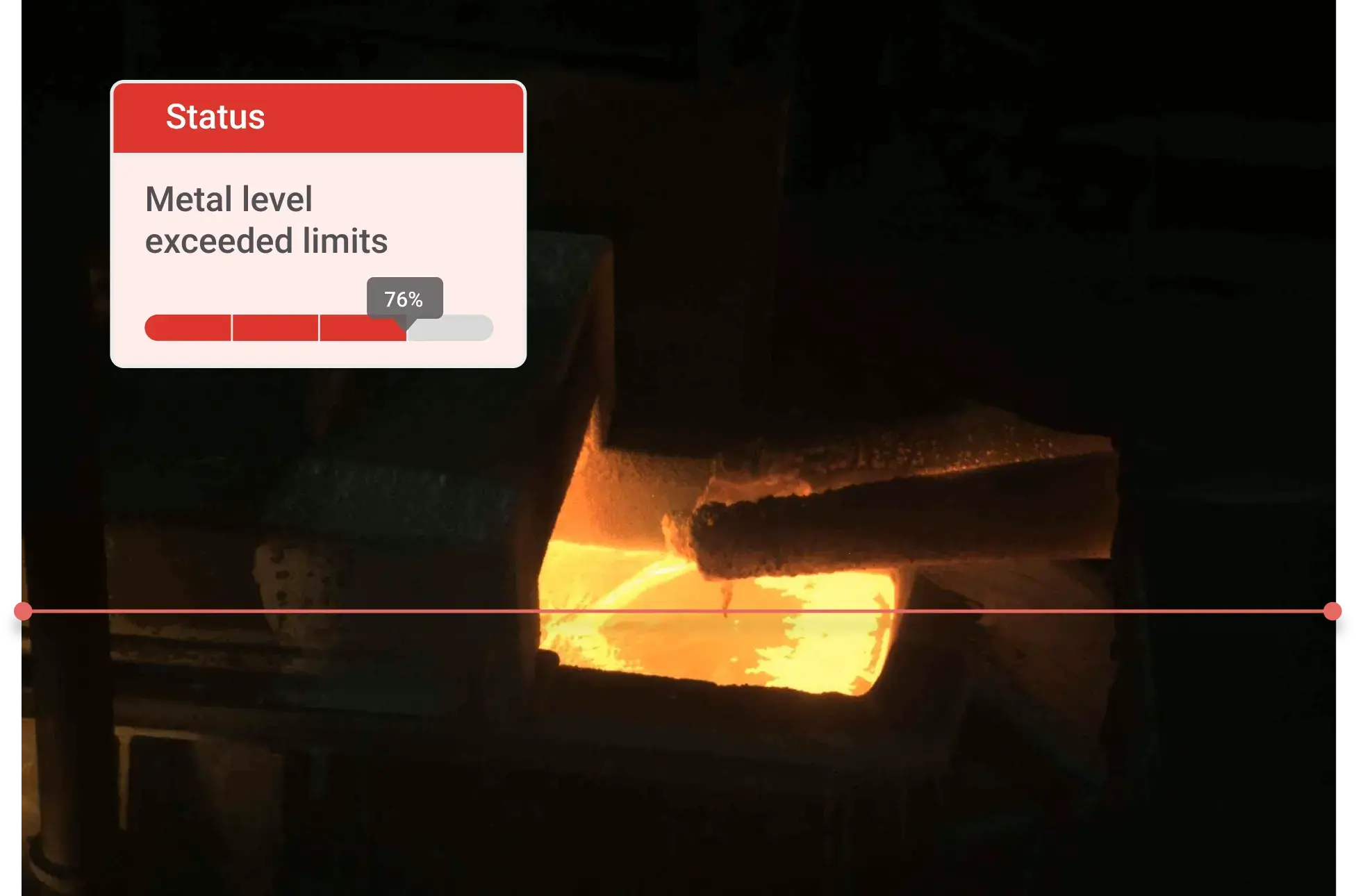

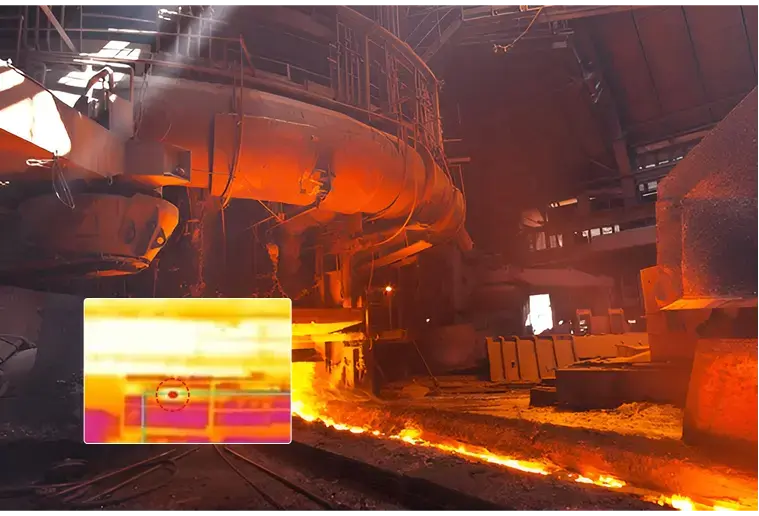

Delayed Fire Hazard Detection

Manual Safety Monitoring and SOP Compliance

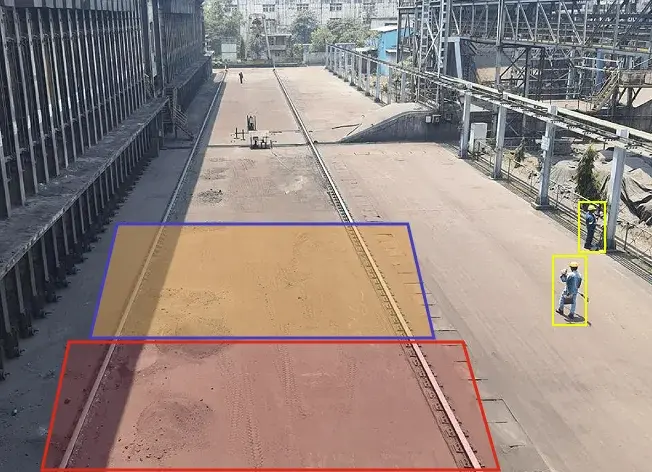

Ineffective Access Control in Hazardous Zones

Equipment Failures and Downtime

Worker Safety

Fragmented Data Infrastructure

Environmental Compliance and Monitoring

What is Vision AI and How It Works in Mining Sectors

Environmental Compliance and Monitoring

Cameras: High-resolution RGB-D, infrared, and LIDAR cameras capture detailed visual data, including depth, heat, and surface structure.

AI/ML Models: Advanced machine learning algorithms process visual data to detect anomalies, identify objects, and generate alerts.

Edge Computing: Enables real-time data inferencing directly at the source to reduce latency.

Dashboards & Analytics: Centralized control rooms access actionable insights through custom dashboards for data analysis and reporting.

Integration with Plant Systems

Vision AI-driven Mining Automation

Applications of Vision AI in Mining Operations

Foreign Particle & Sharp Object Detection

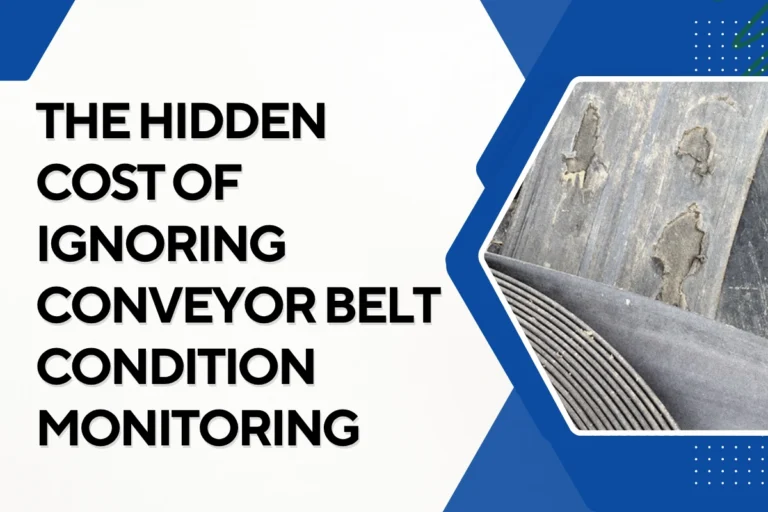

Conveyor Belt Condition Monitoring

Stockpile Volumetric Analysis

Pre-Emptive Fire Detection

SOP Monitoring

PPE Compliance Monitoring

Digital Geo-Fencing

Benefits of Vision AI in Mining Operations

Proactive Operations and Predictive Maintenance

Predictive maintenance enables operators to take proactive measures, addressing potential issues before they lead to failures.

This shift significantly reduces maintenance costs, minimizes downtime, and increases uptime, ultimately enhancing the operational efficiency of mining equipment and processes.

Enhanced Safety and Compliance

Vision AI tracks workers’ PPE (Personal Protective Equipment) in real-time, ensuring that helmets, gloves, harnesses, and reflective vests are always worn.

By automating SOP enforcement, Vision AI helps to ensure that safety guidelines are strictly followed, minimizing the risk of accidents caused by human error.

Moreover, it continuously monitors for potential hazards such as equipment malfunctions, hazardous material exposure, or unsafe worker behavior.

Data-Driven Insights for Process Optimization

The real-time data allows for better-informed decision-making regarding resource allocation, production scheduling, and maintenance planning.

Integration with existing systems like SCADA and control systems further enhances automation across the mining site, enabling optimized process management and resource utilization.

These data-driven insights also support operational transparency, allowing mining companies to identify inefficiencies, streamline workflows, and improve process efficiency.

End-to-End Visibility Across the Supply Chain

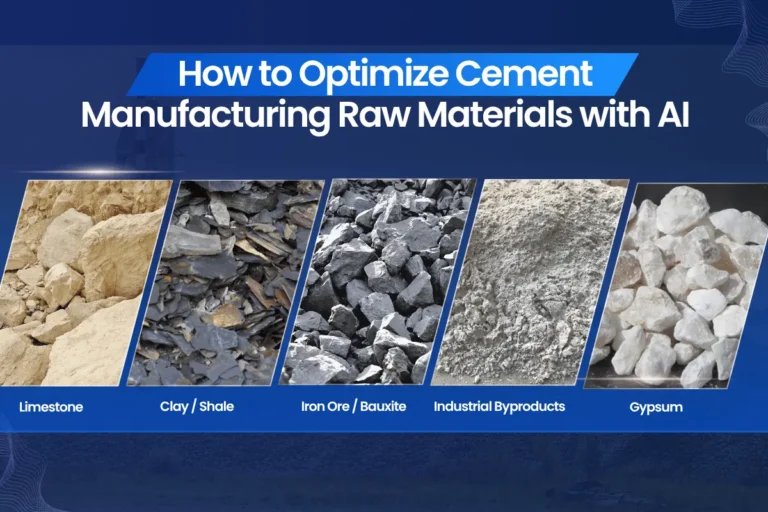

Raw material monitoring ensures consistent quality and size distribution from ore extraction to delivery.

Stockpile volumetric analysis helps accurately measure mass and volume, ensuring proper inventory management and effective resource allocation.

Vision AI also provides real-time insights into the mining environment, monitoring environmental factors such as dust levels, moisture content, and temperature.

This comprehensive supply chain visibility enables mining companies to improve logistics, optimize resource allocation, and streamline operations across multiple mining sites.

Significant Cost Savings

Automated monitoring systems reduce the need for manual inspections, allowing workers to focus on higher-value tasks.

Anomaly detection helps identify and address potential issues with equipment, reducing unplanned maintenance and avoiding costly repairs.

Furthermore, optimized material usage and minimized waste lead to more efficient use of resources, improving the bottom line and boosting profitability.